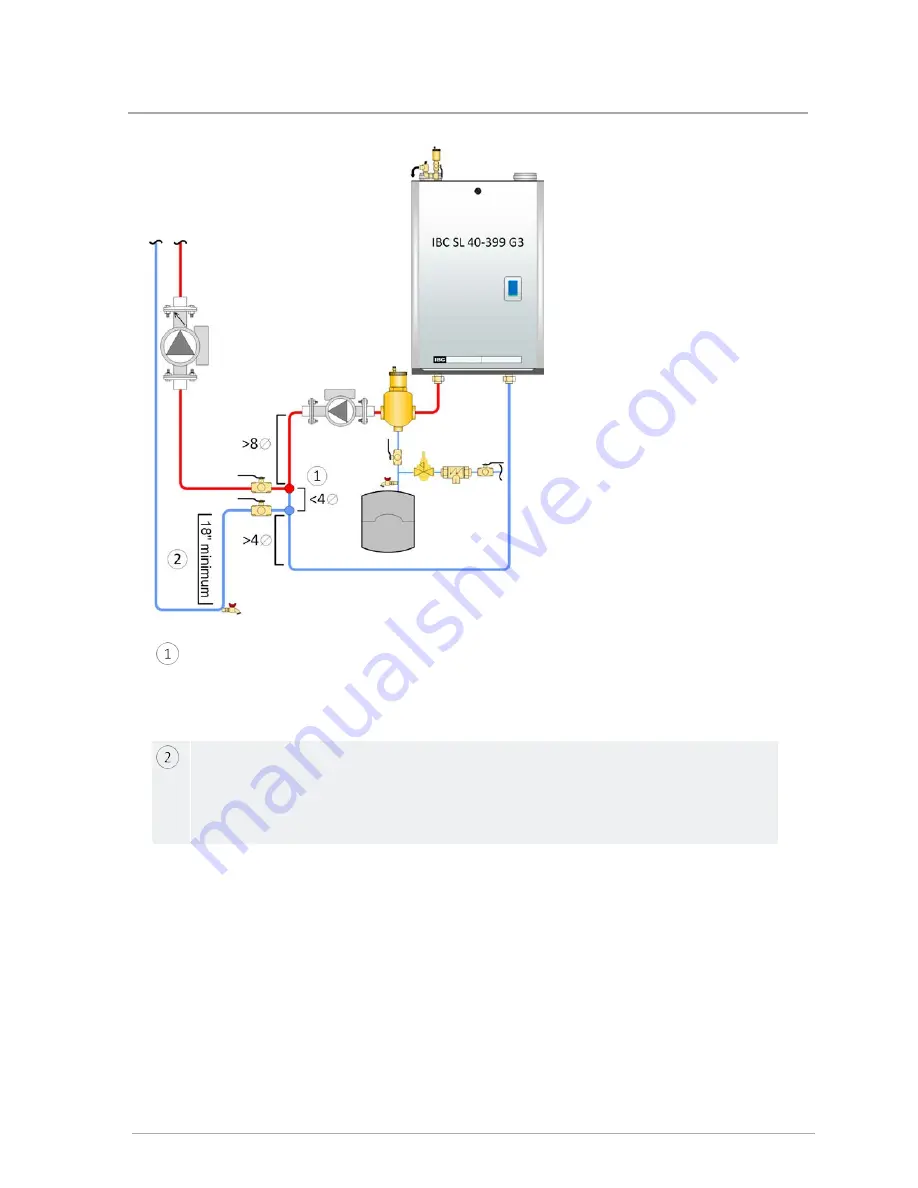

Closely-spaced tees: To avoid induced flow, each set of tees should be installed with

straight piping a minimum of 8 pipe diameters upstream and 4 pipe diameters

downstream, with no elbow or other component that may create turbulent flow. Tees

should be as close together as possible (maximum four pipe diameters apart) and there

should be no restrictions between the fittings that would result in a pressure drop.

Heat Migration: On secondary loops that extend vertically to a load that is above the

primary loop, steps must be taken such as fabricating a thermal trap in the return piping -

minimum 18" (46 cm) drop- to prevent thermal siphoning and heat migration to the load

when there is no demand for heat to that loop. Alternatively, use check valves on both

supply and return of secondary piping.

Figure 32

Primary-secondary piping details with closely-spaced tees

49

3.11.2 System piping

Содержание SL Series

Страница 8: ...Intentionally left empty...

Страница 12: ...Figure 5 Top view SL 40 399 G3 Figure 6 Bottom view SL 40 399 G3 8 Section Specifications...

Страница 14: ...Intentionally left empty...

Страница 64: ...Figure 40 Electric wiring connections 60 Section Installation...

Страница 76: ...Intentionally left empty...

Страница 96: ...Intentionally left empty...

Страница 108: ...Intentionally left empty...

Страница 109: ...105 Appendices Wiring diagrams V 10 Controller electrical diagram Figure 45 Controller electrical diagram...

Страница 110: ...Internal wiring diagram Figure 46 Internal wiring diagram 106 Section Appendices...

Страница 111: ...Sequence of operations Figure 47 Sequence of Operation 107 Sequence of operations...

Страница 113: ...Item Description Part ID Kit Quantity 200 Fan or 240 113 P 311 1 109 Boiler part diagrams SL 26 260 G3...