OPERATION

5-19

HT4001 Instruction Manual

COMMON CUTTING FAULTS

•

Torch pilot arc will initiate, but will not transfer. Causes can be:

1.

Work cable connection on cutting table not making good contact.

2.

Malfunction in HT4001 system. See

Troubleshooting in Maintenance section.

•

Workpiece is not totally penetrated, and there is excessive sparking on top of the

workpiece. Causes can be:

1.

Current is set too low (check

Cut Chart information).

2.

Cut speed is too high (check

Cut Chart information).

3.

Torch parts are worn (see

Changing Consumable Parts).

4.

Metal being cut is too thick.

•

Dross forms on the bottom of the cut - See Dross Conditions on page 5-16.

•

Cut angle not square - See How to Get Better Cut Quality on page 5-15.

•

Short consumable life - See How to Get Longer Consumable Life on page 5-17.

TECHNICAL QUESTIONS

Claims for defective merchandise -- All units shipped from Hypertherm undergo rigorous

quality control testing. However, if your system does not function correctly:

1.

Re-check all pre-installation and installation requirements and connections.

2.

If you are unable to solve the problem, call your distributor. He/she will be able to help

you, or refer you to an authorized Hypertherm repair facility.

3.

If you need additional assistance, call Customer Service at 1-800-643-0030 or Technical

Service at 1-800-643-9878.

.

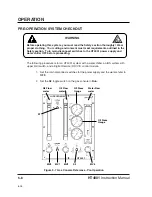

CUT CHARTS

The Cut Charts on the following pages are optimized to provide the best cut angle, least

dross and best cut surface finish. Keep in mind that the charts provide a good starting

point and that optimum cutting must be tuned to the application and materials on site.

Increasing cut speed, lowering the torch standoff, for example, all present certain trade-

offs as mentioned in

How to Get Better Cut Quality. Depending on the cutting

application, it is up to the operator to determine if the trade-offs are acceptable.

Before cutting, check all settings and adjustments and check for damaged torch

parts and worn consumable parts.

Содержание HT4001

Страница 1: ...Plasma Arc Cutting System Instruction Manual 802000 Revision 15 HT4001 EN50199 EN60974 1 ...

Страница 142: ...PARTS LIST 6 6 HT4001 Instruction Manual Figure 6 2 HT4001 Power Supply Inside Front Panel 1a 1b 1c 1d 2 99 2 ...

Страница 148: ...PARTS LIST 6 12 HT4001 Instruction Manual Figure 6 5 HT4001 Power Supply Inside Floor 1 2 3b 3a 3c 3d ...

Страница 152: ...PARTS LIST 6 16 HT4001 Instruction Manual Figure 6 7 HT4001 Power Supply Rear Wall Outside 1 2 6 8 7 4 5 9 3 10 6 95 ...

Страница 239: ...e 2 ...

Страница 240: ...e 3 ...

Страница 241: ...e 4 ...

Страница 242: ...e 5 ...

Страница 244: ...e 7 ...

Страница 245: ...e 8 ...

Страница 246: ...e 9 ...

Страница 247: ...e 10 ...

Страница 257: ...KY ...

Страница 258: ...KY ...

Страница 259: ...KY ...

Страница 260: ...KY ...

Страница 261: ...KY ...

Страница 262: ...KY ...

Страница 263: ...KY ...

Страница 264: ...KY ...

Страница 268: ...KY ...

Страница 269: ...KY ...

Страница 270: ...KY ...