117592

4-11

REV C

from under the mower.

15.

Raise the rear of the mower and remove the jack stands.

Lower the mower.

16.

Lower and secure the seat platform

Warner Clutch Re-gap Adjustment

Procedures

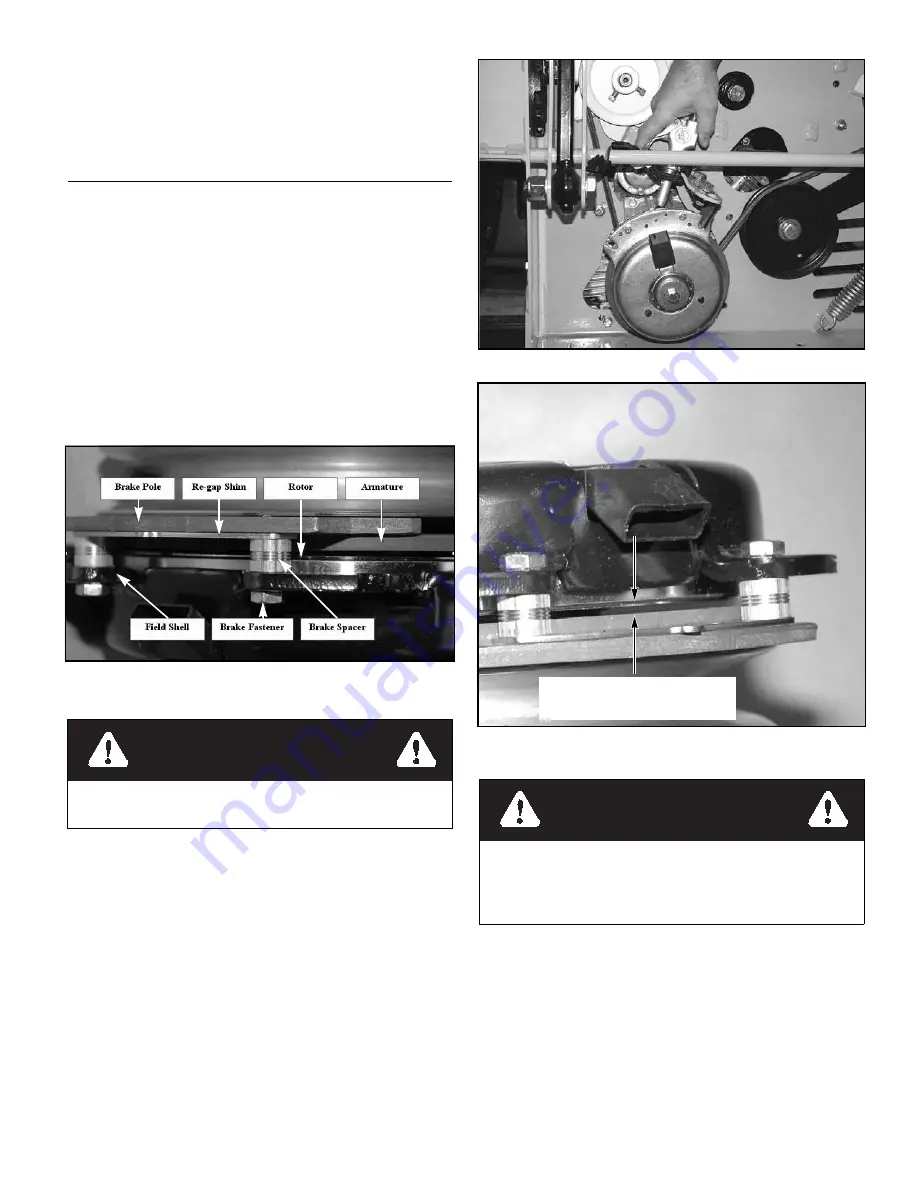

The air gap is only adjustable on clutches that have a

removable shim (see Figure 4-32).

When to remove shim:

When a clutch has worn to the extent that the existing air-gap

is too large to allow for complete clutch engagement (clutch

may engage easily when cold but has problems engaging when

hot), the brake shim can be removed to reduce air gap and allow

the clutch to continue to function.

After verifying that proper voltage and current are supplied to

the clutch, follow the procedure outlined below.

NOTE:

Before proceeding, the clutch must be installed on

the engine crankshaft and the retaining bolt torqued to 45-48 ft-

lbs.

Procedure:

With engine off, key removed and clutch disengaged and

using a pneumatic line, blow out any debris from under the

brake pole and around the aluminum spacers. Figure 4-29

Check the air gap between rotor & armature with feeler gage.

If the gap is less than .070”, then follow the troubleshooting

procedure outlined in Warner Electric P1177 installation

troubleshooting guide available on Warner Electric’s web site-

www.Warnerelectric.com. If the air gap is over .070”, follow the

procedure outlined below. Figure 4-30

1.

Loosen both brake mounting bolts 1/2 to 1 full turn as

shown in Figure 4-31.

2.

Using needle nose pliers, or by hand, take hold of the tab

and remove shim (do not discard shim until proper clutch

function has been confirmed). Figure 4-32

3.

Using a pneumatic line, blow out any debris from under

the brake pole and around the aluminum spacers. Figure

4-29

4.

Re-torque each bolt (M6 X 1) to 120 in.-lbs.

5.

Using a .015” thick feeler gage, verify that a gap is

present between the rotor and armature face on both ends

of the brake pole as shown. Figure 4-33 and Figure 4-34

a.

If the gap is less than .015” the clutch must be

Figure 4-28

WARNING

Always wear adequate eye protection when servicing the

mower.

Figure 4-29

Figure 4-30

WARNING

Do not remove brake pole from field shell/armature. The

brake pole tracks match with the clutch brake and need to

continue to match after shim is removed to ensure proper

brake torque. Figure 4-28

Be certain that the gap between the

rotor and armature face is greater

than .070” prior to shim removal.

Содержание Super Z HD

Страница 1: ...117592 REV C Super Z HD General Service Manual 200 South Ridge Road Hesston Kansas 67062...

Страница 6: ...REV C 1 2 117592...

Страница 10: ...REV C 2 4 117592...

Страница 12: ...REV C 3 2 117592...

Страница 30: ...REV C 5 6 117592...

Страница 40: ...REV C 7 2 117592 Electrical Schematic Kawasaki Mowers with serial number 12122104 and later...

Страница 41: ...117592 7 3 REV C Electrical Schematic Kawasaki DFI...

Страница 42: ...REV C 7 4 117592 Electrical Schematic Briggs Stratton...

Страница 50: ...INDEX PAGE PAGE REV C 1 2 117592...