2-12

r

efrIgeratIon

/ W

IrIng

r

outes

/ C

ontroller

P/N 3143042_B

U.S. & Canada 1-800-922-1919 • Mexico 800-890-2900 • WWW.HUSSMANN.COM

ELECTRONIC CONTROLLER

OPERATION

Follow the tables to use the commands. The

keypad display is located on the front of the

merchandiser.

Follow the LED commands to operate and

control the case’s lighting.

How to see the setpoint:

1. Push and immediately release the SET

key. The display will show the setpoint

value.

2. Push and immediately release the SET

key or wait for 5 seconds to display the

present value again.

How to change the setpoint:

The controller is shipped from the factory

with Type 1 settings. To modify the

temperature for Type 2 application, follow

these instructions:

1. Push and hold the SET key for more than

2 seconds to change the setpoint value.

2. The value of the setpoint will be displayed

and the °C or °F LED starts blinking.

3. To change the setpoint value push the UP

or DOWN arrows within 10 seconds.

4. To memorize the new setpoint value, push

the SET key again or wait 10 seconds.

How to start a manual defrost:

Push and hold the DEF key for more than 2

seconds and a manual defrost will start.

How to lock the keyboard:

1. Keep the UP + DOWN arrow keys

pressed for more than 3 seconds.

2. The PoF message will be displayed and

the keyboard will be locked. At this point

it will be possible to see the setpoint of

the MAX or Min temperature stored

only.

3 If a key is pressed for more than

3 seconds the PoF message will be

displayed.

How to unlock the keyboard:

Press the UP and DOWN arrow keys

together for more than 3 seconds until the

Pon message displays.

Alarms:

P1

Discharge temperature probe failure

P2 Defrost termination probe failure

HA Max temperature alarm

LA Min temperature alarm

How to set defrost start time

The defrost will occur 24 hours after the

controller is first powered up, then every 24

hours after that.

4 • XR75CX I&O Manual

026-1210 Rev 0 09-FEB-2011

4

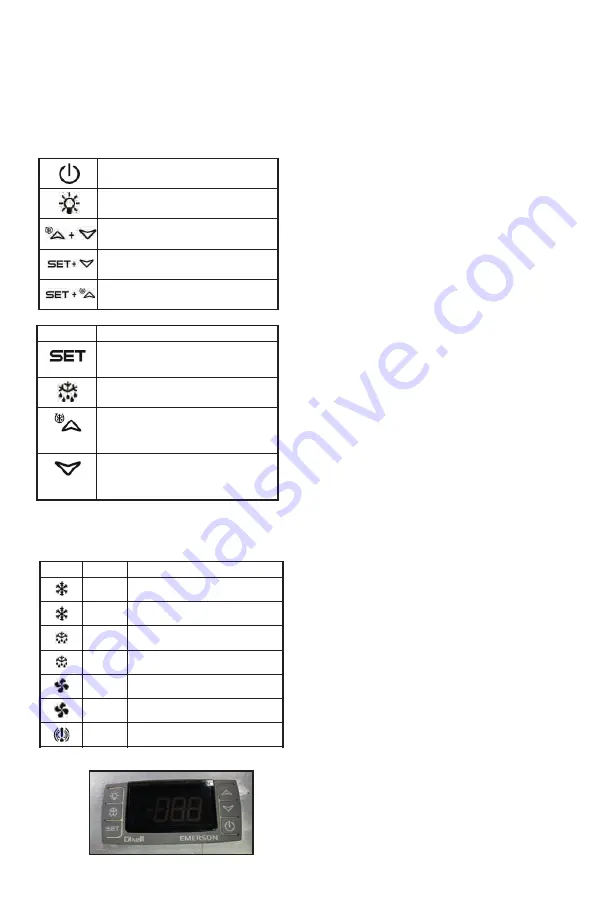

Front Panel

Commands

4.1. Keys and Functions

Table 4-1

shows the keys that are found on the

front panel of the XR75CX controller and their corre-

sponding functions:

4.2. Use of LEDS

Each LED function is described in

Table 4-2

:

Figure 4-1 - XR75CX Front Panel

Key

Function

Press to display target setpoint, to select a pa-

rameter in programming mode, or to confirm

an operation

Starts a manual defrost

Press the UP arrow to see the MAX tempera-

ture, to browse the parameter codes in pro-

gramming mode, or to increase the currently

displayed temperature value.

Press the DOWN arrow to see the MIN tem-

perature, to browse the parameter codes in

programming mode, or to decrease the cur-

rently displayed temperature value.

Table 4-1 - XR75CX Front Panel Keys and Functions

Switches the device ON and OFF, if

onF

=

oFF

Switches the light ON and OFF, if

oA1

=

Lig

Locks/Unlocks the keyboard

To enter programming mode

Returns to room temperature display

LED

Mode

Function

ON

Compressor enabled

Flashing

Anti-short cycle delay enabled

ON

Defrost enabled

Flashing

Drip time in progress

ON

Fans enabled

Flashing

Fans delay after defrost in progress.

ON

An alarm is occurring

ON

Continuous cycle is running

ON

Energy saving enabled

ON

Light ON

ON30

Auxiliary relay ON

ON

Measurement unit

Flashing

Programming phase

Table 4-2 - LEDs

Table 4-1 - XR75CX Front Panel Keys and Functions

4 • XR75CX I&O Manual

026-1210 Rev 0 09-FEB-2011

4

Front Panel

Commands

4.1. Keys and Functions

Table 4-1

shows the keys that are found on the

front panel of the XR75CX controller and their corre-

sponding functions:

4.2. Use of LEDS

Each LED function is described in

Table 4-2

:

Figure 4-1 - XR75CX Front Panel

Key

Function

Press to display target setpoint, to select a pa-

rameter in programming mode, or to confirm

an operation

Starts a manual defrost

Press the UP arrow to see the MAX tempera-

ture, to browse the parameter codes in pro-

gramming mode, or to increase the currently

displayed temperature value.

Press the DOWN arrow to see the MIN tem-

perature, to browse the parameter codes in

programming mode, or to decrease the cur-

rently displayed temperature value.

Table 4-1 - XR75CX Front Panel Keys and Functions

Switches the device ON and OFF, if

onF

=

oFF

Switches the light ON and OFF, if

oA1

=

Lig

Locks/Unlocks the keyboard

To enter programming mode

Returns to room temperature display

LED

Mode

Function

ON

Compressor enabled

Flashing

Anti-short cycle delay enabled

ON

Defrost enabled

Flashing

Drip time in progress

ON

Fans enabled

Flashing

Fans delay after defrost in progress.

ON

An alarm is occurring

ON

Continuous cycle is running

ON

Energy saving enabled

ON

Light ON

ON30

Auxiliary relay ON

ON

Measurement unit

Flashing

Programming phase

Table 4-2 - LEDs

Table 4-1 - XR75CX Front Panel Keys and Functions

4 • XR75CX I&O Manual

026-1210 Rev 0 09-FEB-2011

4

Front Panel

Commands

4.1. Keys and Functions

Table 4-1

shows the keys that are found on the

front panel of the XR75CX controller and their corre-

sponding functions:

4.2. Use of LEDS

Each LED function is described in

Table 4-2

:

Figure 4-1 - XR75CX Front Panel

Key

Function

Press to display target setpoint, to select a pa-

rameter in programming mode, or to confirm

an operation

Starts a manual defrost

Press the UP arrow to see the MAX tempera-

ture, to browse the parameter codes in pro-

gramming mode, or to increase the currently

displayed temperature value.

Press the DOWN arrow to see the MIN tem-

perature, to browse the parameter codes in

programming mode, or to decrease the cur-

rently displayed temperature value.

Table 4-1 - XR75CX Front Panel Keys and Functions

Switches the device ON and OFF, if

onF

=

oFF

Switches the light ON and OFF, if

oA1

=

Lig

Locks/Unlocks the keyboard

To enter programming mode

Returns to room temperature display

LED

Mode

Function

ON

Compressor enabled

Flashing

Anti-short cycle delay enabled

ON

Defrost enabled

Flashing

Drip time in progress

ON

Fans enabled

Flashing

Fans delay after defrost in progress.

ON

An alarm is occurring

ON

Continuous cycle is running

ON

Energy saving enabled

ON

Light ON

ON30

Auxiliary relay ON

ON

Measurement unit

Flashing

Programming phase

Table 4-2 - LEDs

Table 4-1 - XR75CX Front Panel Keys and Functions