7

Stationary Single Stage Vertical Air Compressors

Maintenance (Continued)

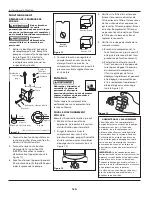

6 . Check belt for signs of excessive

wear . If belt shows signs of wear,

replace it . Check belt for proper

tension / alignment . To adjust belt:

a . Remove belt guard .

b . Remove belt .

c . Loosen the four fasteners holding

the motor to the baseplate .

d . Shift the motor in the proper

direction . Tighten the four

fasteners holding motor to

baseplate . The belt must

be properly aligned when

adjustment is made .

e . To align belt, lay a straightedge

against the face of the flywheel

touching the rim at two places

(See Figure 14) .

f . Adjust flywheel or motor pulley

so that the belt runs parallel to

the straightedge (See Figure 14) .

g . If necessary, use a gear puller to

move the pulley on the motor

shaft . Tighten setscrew after

pulley is positioned .

h . Reattach belt .

i . Reattach belt guard .

MAInTenAnCe SCheDUle

OpeRATIOn

DAIly

Weekly

MOnThly

3 MOnThS

CHECK OIL LEVEL

l

DRAIN TANK

l

CHECK AIR FILTER

l

CHECK SAFETY VALVE

l

CLEAN UNIT

l

CHECK BELT TIGHTNESS

l

CHANGE OIL

l

Figure 14

Touch Rim In

Two Places

Straight Edge

Parallel With Belt

7 . Change oil .

a . Allow compressor to run and

warm up oil . Unplug unit .

b . Position a pan under pump end of

unit .

c . Remove oil drain plug (See

Figures 8 and 9) . Allow oil to

collect in pan .

d . Replace drain plug, fill pump to

full level (See Figures 8 and 9) .

Use Mobil 1 10W-30 synthetic

motor oil .

TeChnICAl SeRVICe

For information regarding the

operation or repair of this product,

please call 1-800-543-6400 .