3

Stationary Single Stage Vertical Air Compressors

Introduction

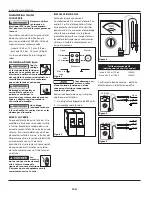

Refer to Figure 1 .

InSTAllInG A ShUT-OFF VAlVe

A shut-off valve should be installed

on the discharge port of the tank to

control the air flow out of the tank . The

valve should be located between the

tank and the piping system .

pressure switch -

Auto/Off Switch - In

the "auto" position, the compressor

shuts off automatically when tank

pressure reaches the maximum preset

pressure . After air is used from the tank

and drops to a preset low level, the

pressure switch automatically turns the

motor back on . In the "off" position,

the compressor will not operate . This

switch should be in the "off" position

when connecting or disconnecting the

power cord from the electrical outlet .

When the pressure switch turns the

motor off you will hear air leaking out

of the pressure switch unloader valve

for a short time . This releases the air

pressure from the discharge tube and

allows the compressor to restart easier .

For units without a manual switch,

whenever the procedures call for

turning the switch to the OFF position,

use the switch at the disconnect instead .

Regulator -

The regulator controls the

amount of air pressure released at the

hose outlet (Sold separately) .

ASMe Safety Valve -

This valve

automatically releases air if the tank

pressure exceeds the preset maximum .

Discharge tube -

This tube carries

compressed air from the pump to the

check valve . This tube becomes very hot

during use . To avoid the risk of severe

burns, never touch the discharge tube .

Check valve -

One-way valve that

allows air to enter the tank, but

prevents air in the tank from flowing

back into the compressor pump .

Belt Guard -

Covers the belt, motor

pulley and flywheel .

Tank Drain Valve -

This valve is located

on the bottom of the tank . Use this

valve to drain moisture from the tank

daily to reduce the risk of corrosion .

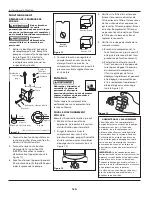

MOUnTInG

Never use the wood

shipping skids for

mounting the compressor.

FLOOR MOUNTING (ALL UNITS)

The compressor feet

MUST

be bolted to

a flat, even, concrete floor or separate

concrete foundation . Vibration isolators

must be

used between the tank leg

and the floor (Part number MP346100AJ

available separately) . Do not draw

bolts tight . Allow the pads to absorb

vibrations . A flexible coupling should be

installed between the tank and service

piping .

This compressor is

extremely top heavy.

The unit must be bolted to the floor

with isolation pads before operating to

prevent equipment damage, injury or

death.

Never install a shut-

off valve between

the compressor pump and the tank.

Personal injury and/or equipment

damage may occur.

pIpInG

Never use plastic

(PVC) pipe for

compressed air. Serious injury or death

could result.

Any tube, pipe, or hose used must have

a pressure rating higher then 150 psi .

Minimum recommended pipe size:

- up to 50 feet long use 1/2 inch

- greater than 50 feet long use 3/4 inch

Larger diameter pipe is always better .

Installation

Disconnect, tag and lock out

power source, then release

all pressure from the system

before attempting to install, service,

relocate or perform any maintenance.

lOCATIOn

This compressor is

not intended for

outdoor installation.

It is extremely important to install the

compressor in a clean, well ventilated

area where the surrounding air

temperature will not be more than

100°F .

Provide a minimum clearance of

18 inches between the compressor

flywheel or fan to the wall and ensure

clear access to the drain valve to

facilitate condensate drainage .

Do not locate the compressor air inlet

near steam, paint spray, sandblast areas

or any other source of contamination .

Tank Drain Valve

Discharge Tube

Belt Guard

Check

Valve

Safety

Valve

Pressure

Switch

Tank

Outlet /

Discharge

Port

Tank

Pressure

Gauge

Figure 1 -

Some compressors may have a

different appearance, but they

have similar parts .