4

Operating Instructions

Installation

(Continued)

electrical Installation

All

wiring

and electrical connections

must be performed by

a qualified electrician

familiar with industrial motor controls.

Installations must be in accordance with

local and national codes.

Disconnect, tag and lock out

power source, then release

all pressure from the system

before attempting to install, service,

relocate or perform any maintenance.

Overheating, short

circuiting and fire

damage will result from inadequate

wiring.

GROUnDInG

This product must be grounded . If the

unit comes with a factory installed

cord, plug the cord into a properly

sized, grounded outlet . For units that

do not have a factory installed cord,

install permanent wiring from the

electrical source to the pressure switch

with a ground conductor connected to

the grounding screw on the pressure

switch . A properly sized cord with a

ground conductor and plug may also be

installed by the user .

Improperly grounded motors

are shock hazards. Make sure

all the equipment is properly

grounded.

WIRInG

Local electrical wiring codes differ from

area to area . Source wiring, plug and

protector must be rated for at least

the amperage and voltage indicated

on the motor nameplate, and meet

all electrical codes for this minimum .

Use a slow blow fuse type T or a circuit

breaker .

Damage to the

motor from

improper electrical voltage or

connection will void the warranty.

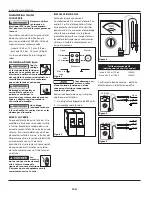

You will need the following for proper

installation:

1 . A 240 Volt double pole circuit

breaker .

2 . A voltage meter .

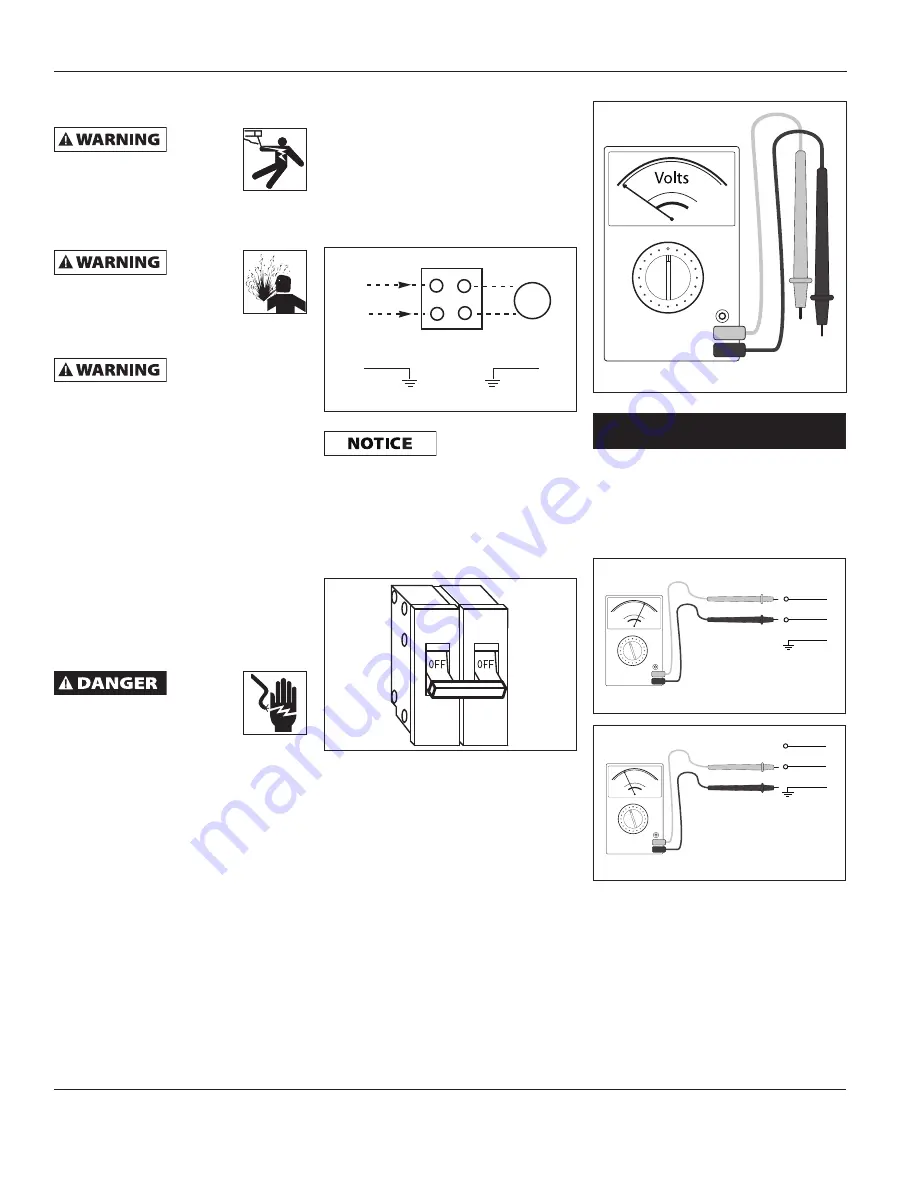

Confirm proper voltage - must be

performed by a qualified electrician .

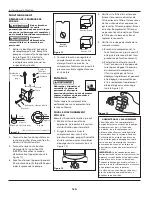

L1

L2

240V

Ground

Pressure

Switch

Line

M

Motor

Figure 2

Figure 3

Minimum wire sizes

(most meet all codes)

Up to 75 feet long

12AWG

Greater than 75 feet

10AWG

Figure 4

Figure 5

Line

Line

Ground

230 / 240

Volts

Figure 6

Line

Line

Ground

120 Volts