The boiler must be installed in a fixed loca-

tion and

only by authorised person

in

compliance with all instructions contained

in this manual. Furthermore, the installation

must be in accordance with current Standard

AS 5601and other regulations as applicable.

Use the template supplied to position all holes.

6.2.1

INSTALLATION

– These boilers can be installed in all normal

domestic environments as a room sealed

multi function boiler.

– These boilers can also be installed in par-

tially covered areas, as per AS5601, with a

maximum ambient temperature of 60°C

and a minimum ambient temperature of -

5°C. It is generally advisable to install the

boilers below weathered roofs, on the bal-

cony or in a protected niche, to protect

them from exposure to weathering agents

(rain, hail and snow). All boilers provide a

standard antifreeze function.

6.2.1.1

Anti-freeze function

The boilers are equipped with anti-freeze

function which activates the pumps and the

burner when the temperature of the water

contained inside the appliance drops to

below value PAR 10. The anti-freeze function

is ensured, however, only if:

– the boiler is correctly connected to the

gas and electricity supply circuits;

– the boiler is constantly fed;

– the boiler ignition is not blocked;

– the essential components of the

boiler are all in working order

In these conditions the boiler is protected

against frost down to an environmental tem-

perature of -5°C.

ATTENTION:

In the case of installation in a place where

the temperature drops below 0°C, the

connection pipes must be protected.

6.2.2

COMPLEMENTARY

ACCESSORIES

For to fix the boiler to the wall, can be sup-

plied on r eques t t he f ixing jig code

8075427, complete with instructions for

assembly.

6.2.3

CONNECTING UP SYSTEM

To protect the heat system from damaging

corrosion, incrustation or deposits, before

installation it is extremely important to

clean the system using suitable products

such as, for example, FERNOX. Complete

instructions are provided with the products

but, for further information please contact

the Hunt Heating technical department.

For long-term protection against corrosion

and deposits, the use of inhibitors such as

FERNOX is recommended after cleaning the

system. It is important to check the con-

centration of t he inhibit or af t er each

system modification and during maintenan-

ce following the manufacturer’s published

instructions. The safety valve drain must be

connected to a collection funnel to collect

any discharge during interventions. If the

heating system is on a higher floor than the

boiler, install the on/off taps supplied in kit

op tional on t he heating sy s t em

flow/return pipes.

WARNING: Failure to clean the heat

s

ystem or add an adequate inhibitor inva-

l

idates the appliance’s warranty.

Gas connections must be made in accor-

dance with current standards and regula-

tions. When dimensioning gas pipes from

the meter to the module, both capacity

volume (consumption) in m

3

/h and gas

density must be taken into account.

The sections of the piping making up the

system must be such as to guarantee a

supply of gas sufficient to cover the maxi-

mum demand, limiting pressure loss

between the gas meter and any apparatus

being used to not greater than:

– 1.0 mbar for family II gases (natural gas);

– 2.0 mbar for family III gases (butane or

propane).

An adhesive data plate is sticked inside the

front panel; it contains all the technical data

identifying the boiler and the type of gas for

which the boiler is arranged.

6.3.1

Filter on the gas pipe

The gas valve is supplied ex factory with an

inlet filter, which, however, is not adequate to

entrap all the impurities in the gas or in gas

main pipes. To prevent malfunctioning of the

valve, or in certain cases even to cut out the

safety device with which the valve is equip-

ped, install an adequate filter on the gas pipe.

6.2.4

SYSTEM FILLING

Filling of the boiler and the system is done by

the system filling (3 fig. 4).

The charge pressure, with the system cold,

must be between

1

and

1.2 bar

.

Filling must be done slowly so as to allow

any air bubbles to be bled off through the air

valves.

Should the pressure have risen well above

the limit expected, discharge the over pres-

sure by opening the pressure-relief valve.

6.2.4.1

Emptying the system

Use the drain tap to empty the system (5

fig. 4). Turn off the boiler before doing this.

6.2.5

FLUES/CHIMNEYS

A chimney or flue for the evacuation of the

combustion products into the atmosphere

must correspond to the requisites prescri-

bed by the laws in force.

In particular, the specific prescriptions of

law relative to boilers with forced draught

(type C) must be respected.

6.2

INSTALLATION

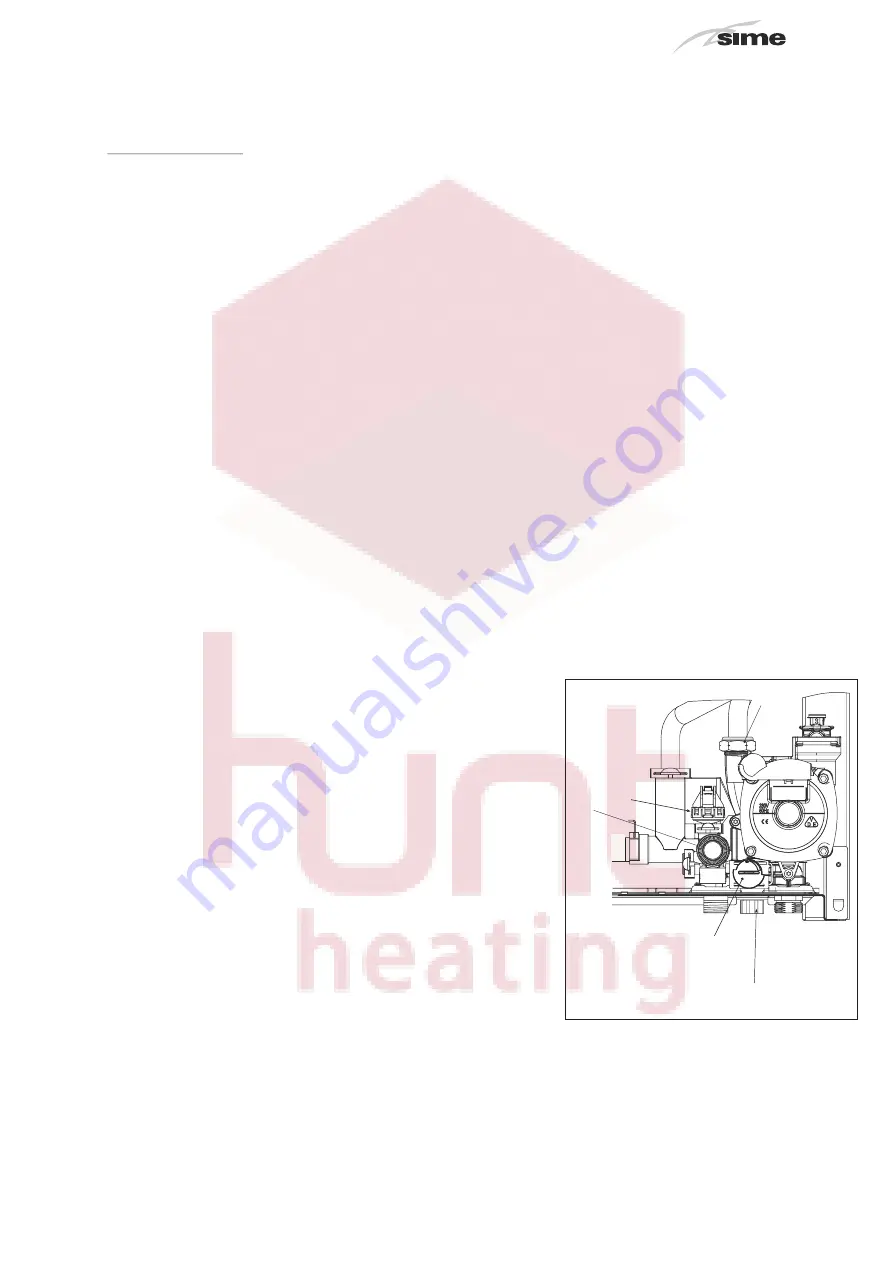

Fig. 4

KEY

1

2 3 BAR safety valve

3 Boiler discharge

Automatic by-pass (blue)

4 Water pressure valve

5 Diverter valve

Page 17 of 34

1

4

5

2

3

MINIMUM CLEARANCES

for INTERNAL BOILERS

This Boiler must have the

following clearances

Above - 200 mm

Below - 200 mm

Sides - 50 mm

Front - 600 mm

min 50 mm to an openable panel

Содержание sime 30e

Страница 33: ...BLANK PAGE Page 33 of 34...