SYSTEM / Control System

T2-1-12

Engine Torque Control

Purpose: To improve fuel consumption rate by

changing the torque curve in response to the

input signals from the work mode selector

switch, shift switch and vehicle speed sen-

sor

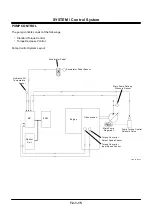

Operation:

1. When MC receives the signal of the selected work

mode, MC detects the shift point.

2. MC has programmed torque curves to be se-

lected in response to the combination of work

mode and speed shift. MC outputs the selection

command signal most suitable to each time to

ECM .

•

When light mode (L) is selected, torque curve 1 or

2 is used.

•

When normal mode (N) or power mode (P) is se-

lected, torque curve 1 is used.

3. ECM carries out alteration control of torque

curves in response to the input torque curve se-

lection command signal.

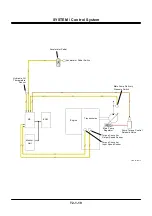

NOTE: In case the signal from the work mode se-

lector switch is not transmitted to MC,

backup control that the work mode is fixed

to the normal mode is made.

NOTE: In case the signal from the shift switch is

not transmitted to MC, backup control that

Torque Curve 1 is selected is made.

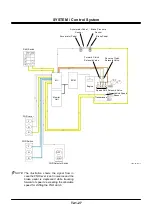

NOTE: Each mode switch of the work mode se-

lector switch is supplied with different volt-

ages for each from the monitor unit. When

the switch selects a mode, MC judges

which mode has been selected by the input

voltage.

NOTE: The shift switch has two switches, and the

combination of their ON varies depending

on each speed shift. The controller judges

which speed shift has been selected by the

combination of the two input signals.

Engine

Torque

Engine

Speed

1

2

Conceptual Diagram of

Engine Torque Curve

Содержание ZW180

Страница 1: ......

Страница 2: ......

Страница 8: ...4GDT 1 2 Blank ...

Страница 10: ...GENERAL Specification T1 1 2 Blank ...

Страница 38: ...GENERAL Component Specifications T1 3 14 Blank ...

Страница 39: ...MEMO ...

Страница 40: ...MEMO ...

Страница 42: ...4GDT 2 2 Blank ...

Страница 56: ...SYSTEM Control System T2 1 14 Blank ...

Страница 82: ...SYSTEM Control System T2 1 40 Blank ...

Страница 92: ...SYSTEM Control System T2 1 50 Blank ...

Страница 106: ...SYSTEM Control System T2 1 64 Blank ...

Страница 116: ...SYSTEM ECM System T2 2 10 Blank ...

Страница 128: ...SYSTEM Hydraulic System T2 3 12 Blank ...

Страница 147: ...SYSTEM Hydraulic System T2 3 31 Blank ...

Страница 150: ...SYSTEM Hydraulic System T2 3 34 Blank ...

Страница 165: ...SYSTEM Electrical System T2 4 15 T4GD 02 04 019 Battery Relay Battery SC FC L L B E D Alternator B Regulator F R ...

Страница 184: ...SYSTEM Electric System T2 4 34 Blank ...

Страница 185: ...MEMO ...

Страница 186: ...MEMO ...

Страница 195: ...COMPONENT OPERATION Pump Device T3 1 7 Blank ...

Страница 210: ...COMPONENT OPERATION Control Valve T3 2 2 Component Layout T4GB 03 02 003 1 2 3 4 5 7 8 9 10 11 7 6 ...

Страница 212: ...COMPONENT OPERATION Control Valve T3 2 4 T4GB 03 02 003 1 2 3 4 5 7 8 9 10 11 7 6 ...

Страница 214: ...COMPONENT OPERATION Control Valve T3 2 6 T4GB 03 02 003 1 2 3 4 5 7 8 9 10 11 7 6 ...

Страница 226: ...COMPONENT OPERATION Control Valve T3 2 18 Blank ...

Страница 232: ...COMPONENT OPERATION Control Valve T3 2 24 Blank ...

Страница 239: ...COMPONENT OPERATION Hydraulic Fan Motor T3 3 7 T4GB 03 03 005 7 8 From Fan Pump P B A 12 T To Hydraulic Oil Tank ...

Страница 248: ...COMPONENT OPERATION Steering Pilot Valve T3 4 6 Blank ...

Страница 258: ...COMPONENT OPERATION Steering Valve T3 5 10 Blank ...

Страница 274: ...COMPONENT OPERATION Pilot Valve T3 6 16 Blank ...

Страница 282: ...COMPONENT OPERATION Pilot Valve T3 6 24 Blank ...

Страница 299: ...COMPONENT OPERATION Ride Control Valve T3 8 5 Blank ...

Страница 306: ...COMPONENT OPERATION Ride Control Valve T3 8 12 Blank ...

Страница 316: ...COMPONENT OPERATION Drive Unit T3 9 10 Forward Clutch Shaft T4GD 03 09 005 Reverse Clutch Shaft T4GD 03 09 006 ...

Страница 345: ...COMPONENT OPERATION Drive Unit T3 9 39 T107 02 07 005 1 Spool 2 Spring 3 Solenoid T P S a a 1 2 3 ...

Страница 348: ...COMPONENT OPERATION Drive Unit T3 9 42 Blank ...

Страница 371: ...MEMO ...

Страница 372: ...MEMO ...

Страница 374: ......