28 Service

NOTICE: INDIVIDUAL BOLT TORQUES

SHOULD BE ACHIEVED NO MORE THAN 2

TIMES IN THE TIGHTENING CYCLE.

11. Reinstall belts and reposition backwrap

idler.

FIGURE 57 PHOTO NO. 3010C

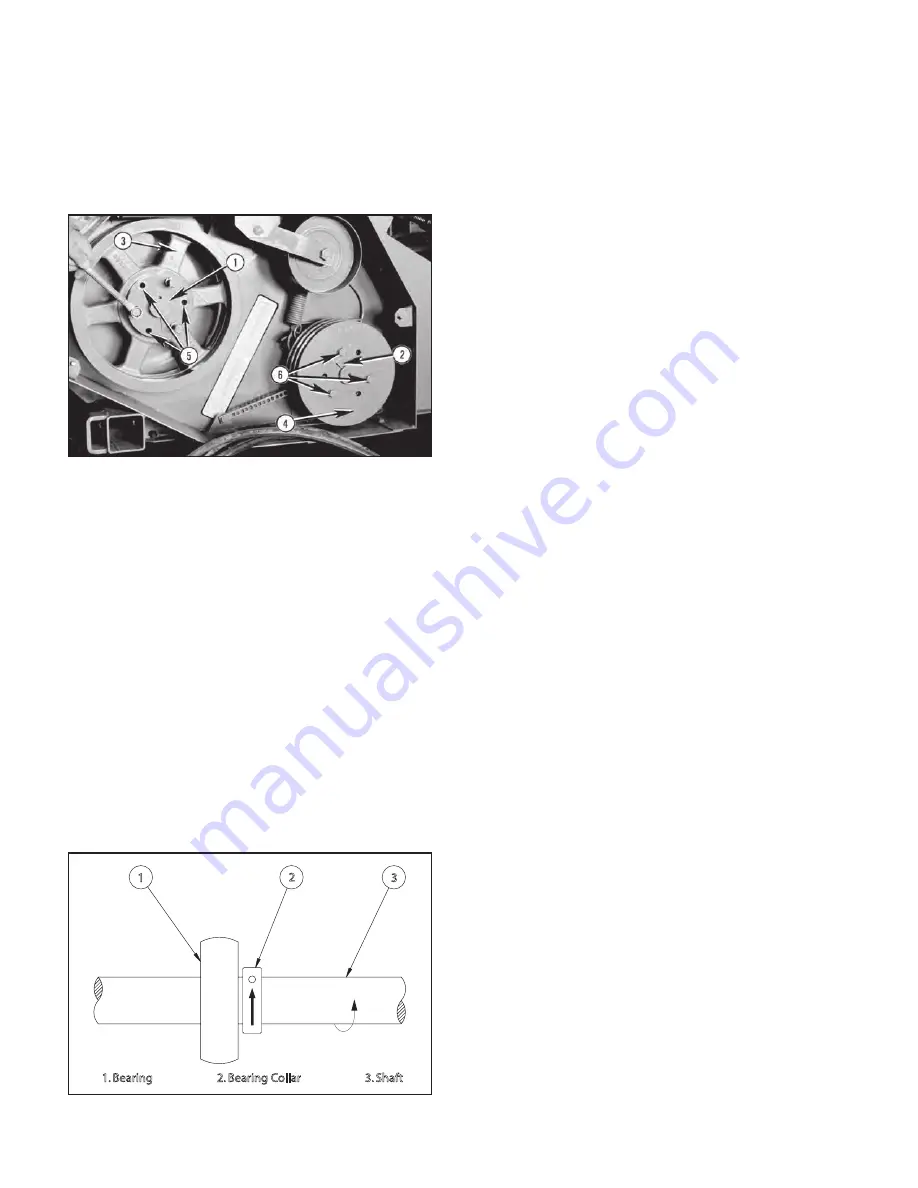

DRIVE SHAFT BEARING

The front drive shaft bearing Item 1 may have an

eccentic lock collar Item 2. To loosen, remove

3/8” Allen set screw therein. With a drift, drive

collar Item 2 OPPOSITE to direction of rotation

of shaft Item 3. When reinstalling bearing, drive

collar Item 2 in SAME DIRECTION as rotation

of shaft Item 3 and retighten set screw. If the

front drive bearing has two set screws, remove

set screws. When reinstalling, tighten both set

screws.

Servicing this bearing requires removing the

driver sheave. See Figure 56, page 27. Paint

must be polished off drive shaft to permit bear-

ing removal.

1

2

3

1. Bearing 2. Bearing Collar 3. Shaft

FIGURE 58 DWG. NO. 2256A

WHEEL BEARINGS & SEALS

HINIKER shredders are equipped with O.D. rid-

ing triplex (3 labyrinths) seals. They also have

a replaceable seal riding ring Item 6 in Photo

3011 and zerk relube in the hub. This system

is highly effective when properly installed and

maintained.

IMPORTANT. WHEEL SEAL AND RIDING RING

MUST BE INSTALLED IN THE RIGHT DIREC-

TION, PROPERLY PRE LUBED AND THE HUB

FULLY PACKED WITH LUBE. IGNORING PRO-

CEDURES BELOW WILL RESULT IN PREMA-

TURE CONTAMINATION AND FAILURE.

1. Remove hub, inboard bearing cone Item 1,

outboard bearing cone Item 2 and seal Item

3 from spindle. Thoroughly clean hub’s in-

terior grease cavity, both bearing cups Item

4, cones, hub cap Item 5 and pre load hard-

ware.

2. Discard old seal Item 3 and inspect bearings

for deterioration. Replace both cups and

cones if necessary. Generally, seal riding

ring Item 6 should be replaced when doing

wheel hub maintenance.

IMPORTANT: PRESS SEAL RIDING RING

INTO HUB WITH INTERIOR EDGE FLANGE

TOWARD INBOARD BEARING CUP. MANU-

ALLY WORK LUBE INWARD BETWEEN 3

SEAL LABYRINTHS BEFORE INSTALLING.

CAREFULLY START NEW SEAL ITEM 3 ONTO

SPINDLE WITH BEARING CONE (1) WHICH

CAN BE SEATED WITH A 3/16” PUNCH OR

1 1/2” I.D. DRIVER. INSURE SEAL IS NOT

CROOKED AND IS INSTALLED WITH ITS

SHARP EDGED INSIDE FLANGE TOWARD

THE OUTBOARD SPINDLE END. THE OP-

POSITE (SMOOTH) SEAL FACE IS USUALLY

MARKED “OUTSIDE”. THIS MUST ALWAYS

FACE THE SPINDLE’S INBOARD END, OTH-

ERWISE THE SEAL WILL NOT FUNCTION

CORRECTLY.

4. Install hub, outboard bearing cone Item 2,

end washer and adjusting nut. Adjust nut

with a HAND WRENCH ONLY. Tighten un-

til seal is seated and bearings substantially

drag, then back nut off 1/6 turn to insert and

spread cotter.

5. Use zerk to fully lube hub cavity and

bearings, while rotating hub, and until

lube emerges through outboard bearing.

Содержание 5710

Страница 2: ......

Страница 12: ...10 Decal Location FIGURE 23 520 03139 Danger Shield Missing FIGURE 24 71504131 Danger Keep Flippers ...

Страница 50: ...NOTES 48 Notes ...