24 Service

Periodically inspect the rotor assembly for bro-

ken or missing knives. Immediately replace

those so indicated because they will cause the

rotor to run out of balance. HINIKER knives are

sold individually, however to maintain balance.

IMPORTANT: REPLACE KNIVES IN NEAR-

EST OPPOSITE (180° APART) SETS. ALSO,

REPLACE CORRESPONDING IDENTICAL

KNIVES AT OTHER END OF ROTOR.

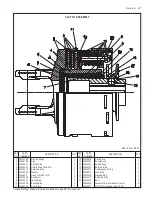

Shredder/choppers are equipped with 32 cup

knives Item 1 in Photo 3215. They are retained

with an equal number of 1/2” x 3” grade 5 car-

riage bolts Item 2, 1/2” x 1 1/4” grade 5 carriage

bolts Item 3 and 64 type B locknuts.

IMPORTANT: WHEN SERVICING KNIVES, AL-

WAYS DISCARD ANY LOCKNUT THAT HAS

BEEN LOOSENED. DO NOT REPLACE HARD-

WARE WITH ORDINARY BOLTS AND NUTS.

INSURE THEY ARE RETORQUED TO 58-82

FT/IBS. (79-112 N/M.). CARRIAGE BOLTS

WITH HEADS ITEM 4, AND NUTS ITEM 5,

SHOULD ALWAYS LEAD DIRECTION OF RO-

TOR ROTATION.

FIGURE 50 PHOTO NO. 3215

SHEARBAR

Shearbar Item 1 in Photo 3216 has slots suffi-

cient to give 3/4” fore/aft adjustment. It is factory

adjusted to the furthermost FORWARD position

Item 2. This provides 3/4” theoretical clearance

from the rotor knives. As rotor knives wear, or

better chopping/shredding is needed, move the

shearbar rearward. If knives are worn unevenly,

hold LONGEST knife out toward cutterbar to

check clearance. It is not recommended to adjust

the shearbar closer than 1/4” to the rotor knives.

CLOSER SHEARBAR/ROTOR CLEARANCE

INREASES POWER REQUIREMENTS.

IMPORTANT: THE SHEARBAR IS RETAINED

WITH (6) 1/2” X 1” GRADE 5 CARRIAGE

BOLTS ITEM 3 AND TYPE F LOCKNUTS.

AFTER ANY ADJUSTMENT, INSURE THESE

BOLTS ARE RETORQUED TO 58-82 FT/IBS.

(79-112 N/M.).

Failure to maintain factory bolt torque may cause

loosening and subsequent shearbar entangle-

ment with rotor knives.

FIGURE 51 PHOTO NO. 3216

BELTS

HINIKER chopper/shredders are EQUIPPED

ONLY WITH PREMIUM GRADE MATCHED

BELTS. Do not replace these with “garden va-

riety” UNMATCHED belts because their power

transmission capability, and durability, will be

degraded.

NOTICE: ADEQUATE TENSION IS NECES-

SARY FOR FULL POWER TRANSMISSION

AND SATISFACTORY BELT PERFORMANCE.

This is obtained by following instructions on de-

cal located on endplate inside end shield.

Содержание 5710

Страница 2: ......

Страница 12: ...10 Decal Location FIGURE 23 520 03139 Danger Shield Missing FIGURE 24 71504131 Danger Keep Flippers ...

Страница 50: ...NOTES 48 Notes ...