18 Operation

If an operator does not properly manage the

above, it will result in erratic PTO speeds. This

may cause the machine to plug and /or “dribble”

material at the delivery deflector. Also, less sat-

isfactory shredding will result.

WARNING: DEATH OR SERIOUS INJU-

RY CAN RESULT. NEVER STAND BE-

HIND THE DISCHARGE SPOUT, OR IN

THE TRAILING WAGON WHEN THE MACHINE

IS RUNNING. NEVER REACH INTO ANY PART

OF THE DISCHARGE PATH WHEN THE MA-

CHINE IS RUNNING.

WARNING: DEATH OR SERIOUS IN-

JURY CAN RESULT. DISENGAGE

PTO, STOP TRACTOR ENGINE, SET

BRAKES , REMOVE KEY AND ALLOW EQUIP-

MENT TO COME TO A COMPLETE STOP BE-

FORE CLEANING, UNCLOGGING, LUBRICAT-

ING, OR OTHERWISE SERVICING, ANY PART

OF THIS EQUIPMENT.

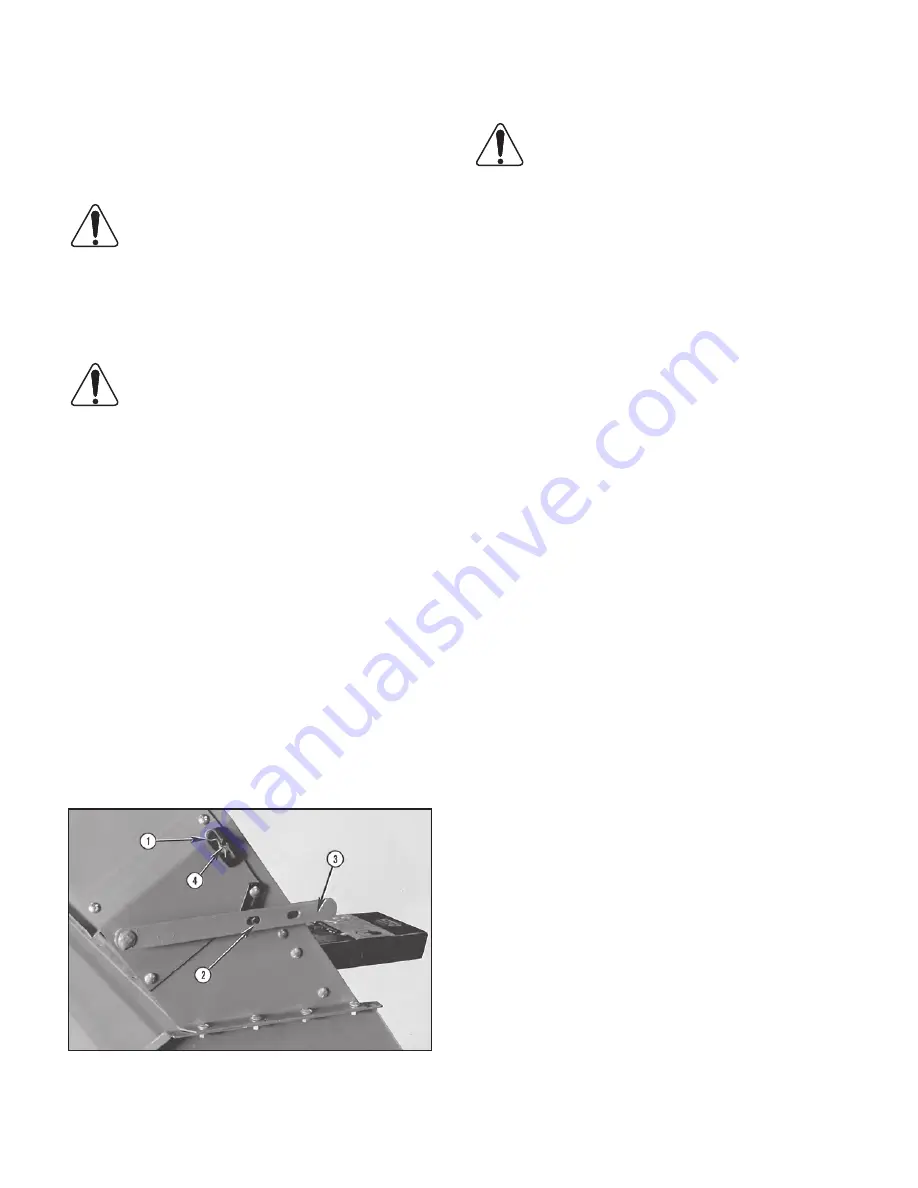

The Hiniker 5710 chopper/shredder can be

easily switched from CHOPPING/LOADING to

SHREDDING ONLY by pulling each side Q.A.

hairpin Item 1 in Photo 3224 from control arm

retention post Item 2. Then swing control arm

Item 3 upward and snap it over retention post

Item 4. Replace Q.A. hairpin Item 1 in each side

retention post Item 4. Remove the SMV emblem

from the socket and store it for use when travel-

ling on the road.

Reverse this procedure for switching from

SHREDDING ONLY to CHOPPING/LOADING.

FIGURE 39 PHOTO NO. 3224

STORAGE

WARNING: DEATH OR SERIOUS IN-

JURY CAN RESULT. DISENGAGE

PTO, STOP TRACTOR ENGINE, SET

BRAKES, REMOVE KEY AND ALLOW EQUIP-

MENT TO COME TO A COMPLETE STOP BE-

FORE CLEANING, UNCLOGGING, LUBRICAT-

ING, OR OTHERWISE SERVICING, ANY PART

OF THIS EQUIPMENT.

Do not store the chopper/shredder outside be-

tween seasons of use. That lowers resale/trade

in value.

The following will insure equipment is in top op-

erating condition at start of next season.

1. Open end shield and thoroughly clean out

dirt and trash. Clean out any other trash

hanging on unit. Check drive shaft and gear-

box bearing seals for trash entanglement.

2. Back off backwrap belt idler to relax tension

on “V” belts. Inspect belts for wear.

3. Clean debris from PTO ends and insure

safety shield freely rotates.

4. Relube machine and check gearbox lube

level.

5. Clean rust off exposed surfaces and repaint

any requiring it. Also check for any loose

hardware.

6. Inspect rotor assembly for lost, broken, or

worn out knives. Replace these as required.

Also, replace any other deteriorated parts,

especially decals and reflectors.

7. Ensure rockshaft lockup bolt is in its operat-

ing position. See Figure 31 on page 12. This

permits ratchet jack, or aftermarket hydrau-

lics, to be used elsewhere.

Содержание 5710

Страница 2: ......

Страница 12: ...10 Decal Location FIGURE 23 520 03139 Danger Shield Missing FIGURE 24 71504131 Danger Keep Flippers ...

Страница 50: ...NOTES 48 Notes ...