Malfunction

Cause

Rectification

Shearing unit is noisy or

vibrates.

The belt is slipping.

Have the belt replaced.

Bearing faulty.

Have the bearing replaced.

Motor gets hot.

Bearing faulty.

Have the motor replaced.

Ventilation screen dirty.

Clean ventilation screen.

Malfunctions in the rigid

drive downtube / flexible

drive and / or shearing

handpiece.

Have fault rectified.

Shearing plant cannot

be switched off.

Switch faulty.

Have the switch replaced.

6

Environmental protection and waste disposal

6.1

Introduction

The operator bears the responsibility for disposing of the machine in the

proper manner. Observe the relevant regulations applicable in your country.

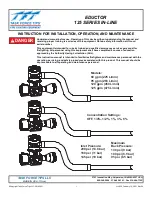

6.2 Material groups

Please hand this in to a service point or your local specialist electrical work-

shop when the machine is to be dismantled.

Material

contained in pos. X taken from Diag. 1

Rubber

45

Polyamide PA

1/3/21/44/47/56

Polypropylene PP

42

POM

20/34

Polychloroprene/Polyester 17

Santoprene TPE

48

Iron/steel

5/6/7/8/14/15/18/19/23/24/25/26/27/28/29/31/32/33/

35/37/39/40/41/46/52/53/54/55

Copper

45

Brass

38/43

Aluminium

16

other substances

2/4

Electronics

11/12/13/22/38

7

Contact address

The sales point or company specified on your guarantee certificate are

authorised service points, or, alternatively, refer to the nearest service point

in your area.

EVO Shearing Plant – Translation of the original instructions

13

Содержание EVO/H

Страница 159: ......

Страница 160: ......

Страница 162: ...A2 2 4 5 3 ...

Страница 163: ...8 A3 6 7 ...