Heat & Glo • SL-750TRS-IPI-D, SL-550TRS-IPI-D, SL-350TRS-C • InD • 2065-985 Rev. o • 3/07

30

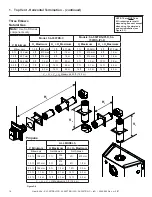

Assembling DVP-12A Slip Sections

The outer

À

ue of the slip section should slide over the outer

À

ue of the pipe section and into (inner

À

ue) the last pipe

section (see Figure 8.6) .

Slide together to the desired length, making sure that a

1-1/2 inch outer

À

ue overlap is maintained between the

pipe section and slip section.

The pipe and slip section need to be secured by driving

two screws through the overlapping portions of the outer

À

ues using the pilot holes (see Figure 8.7).

This will secure the slip section to the desired length and

prevent it from separating. The slip section can then be

attached to the next pipe section.

If the slip section is too long, the inner and outer

À

ues of

the slip section can be cut to the desired length.

Assembling Minimum Installations (MI) Sections

MI sections are non-unitized so that they can be cut to a

certain length. Cut these sections to length from the non-

expanded end (see Figure 8.5).

They can then be attached by

¿

rst connecting the expanded

end of the MI inner

À

ue with the inner pipe from the adjacent

pipe section and securing with three screws. The expanded

portion of the MI inner

À

ue must overlap completely with

the unexpanded end of the adjacent pipe section.

The outer

À

ue can then be inserted into the adjacent outer

À

ue expanded end and attached to the next pipe section

with three screws. The other end of the MI pipe section can

then be attached by

¿

tting another pipe section to it and

snapping it together, as normal.

Figure 8.6 Slip Section Pilot Holes

Figure 8.7 Screws into Slip Section

Figure 8.5