P - 2

9)

Attach the driveline to the tractor PTO and implement PIC. Make sure each

end is firmly attached to its respective shaft.

10)

Make sure driveline does not bottom out when the implement is fully

raised, and that at least 1/3 of the tube is engaged when the implement is at its

lowest height.

LUBRICATION

Always wear adequate safety equipment when performing any maintenance

LUBRICATION OF THE UNIVERISAL JOINT

o

Rotate the shielding until opening the access hole. Lubricate, and close

the hole by rotating the shielding.

LUBRICATION OF THE 650 CV JOINT

o

Rotate the shell to expose the grease fitting and inject grease.

LUBRICATION OF THE TELESCOPING TUBES

o

If grease fittings are not provided, separate the two halves of the

driveline and manually lubricate the telescoping tubes.

Check that all components are in good condition and properly lubricated

before using the driveline. Clean and re-lubricate the driveline before storage

at the end of the season.

o

Lubrication the 650 type 70° CV joint every 8 hours.

o

Lubricate all other components every 50 hours.

o

Pump grease into the crosses until it purges from the bearing caps.

o

Inject grease gradually and avoid pumping the grease gun violently with

resulting high delivery pressure.

o

Use NLGI grade 2 grease.

o

Before storage at the end of the season remove any grease that has

accumulated inside the CV joint shield.

Replace worn or damaged parts with genuine Bondioli & Pavesi spare parts.

o

Do not modify or tamper with any part of the driveline.

o

For any operations not explained in this manual, consult your implement

dealer or manufacturer, or your local Bondioli & Pavesi representative.

Содержание PT-6 FSS

Страница 1: ...Model PT 6 FSS Fertilizer and Lime Spreader SERIAL __________________ WORK ORDER ___________...

Страница 2: ......

Страница 8: ......

Страница 12: ......

Страница 13: ...Fertilizer and Lime Spreader Safety...

Страница 17: ...S 4 PTO SAFETY DECAL...

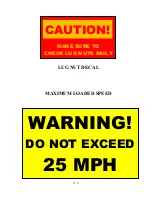

Страница 18: ...S 5 LUG NUT DECAL MAXIMUM LOADED SPEED MAKE SURE TO CHECK LUG NUTS DAILY CAUTION WARNING DO NOT EXCEED 25 MPH...

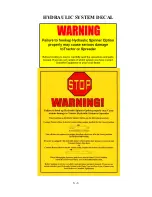

Страница 19: ...S 6 HYDRAULIC SYSTEM DECAL...

Страница 20: ...S 7 ROTATING CHAIN WARNING ROTATING SPINNERS WARNING...

Страница 21: ...PTO Shaft Adjustment And Maintenance...

Страница 24: ......

Страница 25: ...Section 1 Basic Information...

Страница 26: ...1 1 6PT FSS...

Страница 27: ...1 2...

Страница 29: ...Section 2 PTO Drive Spinners...

Страница 33: ...2 4...

Страница 36: ...2 7 Hydraulic Cylinder Engagement Assembly...

Страница 38: ......

Страница 39: ...PTF 71 2 RZ PTO Drive Spinner Gear Case Assembly and Parts List...

Страница 43: ...Section 3 Full Press Wheel Drive Assembly...

Страница 44: ...3 1...

Страница 47: ...3 4...

Страница 48: ...3 5...

Страница 49: ...3 6 Hydraulic Cylinder Engagement Assembly...

Страница 51: ...PTF 71 2 RZ FP Full Press Wheel Drive Spinner Gear Case Assembly and Parts List...

Страница 55: ...Section 4 Press Wheel for Plug to Tractor Hydraulic Spinners...

Страница 58: ...4 3...

Страница 61: ...4 6 Hydraulic Cylinder Engagement Assembly...

Страница 63: ...Section 5 Hydraulic Spinners...

Страница 64: ...5 1...

Страница 67: ...5 4...

Страница 68: ...5 5...

Страница 74: ......

Страница 75: ...Section 6 Flow Divider Assembly...

Страница 76: ......

Страница 77: ...5 4...

Страница 79: ...Section 7 Rigid Axle Assembly...

Страница 80: ...7 1 6 Bolt 7 000 per Pair Hub Assembly J I H G A F E C B D L K...

Страница 82: ...7 3 8 Bolt 12 000 per Pair Hub Assembly J I H G A F E C B D L K...

Страница 85: ...Section 8 Basic Set Up Operation...

Страница 88: ...8 3...

Страница 90: ......

Страница 91: ...Section 9 Maintenance Troubleshooting...

Страница 97: ...Section 10 Spread Pattern...

Страница 101: ...10 4 Data Recording...

Страница 102: ...10 5 Data Recording Unacceptable Pattern Acceptable Pattern...

Страница 104: ...10 7 Acceptable Pattern Using a 3 Pass Switchback Driving Method...

Страница 106: ...10 9 Notes...