9 - 4

C)

Remove retaining ring from flow control valve.

1)

With punch and hammer, knock lever spool from valve body.

CAUTION -

Be

sure to mark in some manner top of spool before removing.

2)

Clean thoroughly, area of housing from which lever spool was removed.

3)

Clean thoroughly the lever spool outer area and blow out all holes with high

pressure air hose.

Reassemble

as taken apart, making sure, spool is replaced with area you marked in the same

position.

If

problem has not been eliminated, continue to investigation procedure

D

.

NOTE:

The following investigation should be carried out very carefully and exactly as

outlined for there is no relief system available for this procedure and if pump is working

properly excessive pressure will build up immediately and cause damage if instructions are not

carried out precisely.

D)

Setting pressure for spinners.

1)

Run unit empty at ordinary operating speed (engine RPM’s) for approximately 10

minutes, to allow hydraulic oil to reach operating temperatures.

2)

Disengage PTO and install pressure gauge into “CF” port on flow control valve.

(Refer to hydraulic flow control valve drawing – page 3-7)

3)

Set lever on flow control valve on 10.

4)

Engage P.T.O. Rev truck engine up to approximately 2000 RPM.

5)

Slowly release clutch while watching pressure gauge.

6)

Pressure gauge should read 2000 PSI.

If

not, adjust pressure in accordance to investigation procedure

E

.

E)

Adjusting Hydraulic Flow Control Valve Pressure.

1)

Remove cap nut on flow control valve (located on top of valve)

2)

Using a 5/16” Allen wrench turn adjustment screw “IN” to increase pressure or

“OUT” to decrease pressure.

3)

Turn adjustable screw on half turn, and then check pressure setting as outlined

above.

i.

Be sure to count number of turns you adjust screw.

4)

Continue this procedure until pressure gauge reads 2000 PSI.

i.

If a 2000 PSI reading is reached on the gauge replace relief valve cover nut.

ii.

If screwing in on the relief adjusting screw had none or little effect on the

pressure, back adjusting screw out to its original position.

NOTE:

If unable to obtain 2000 PSI contact your local dealer or Chandler Equipment Service

Department at 1-800-243-3319

Содержание PT-6 FSS

Страница 1: ...Model PT 6 FSS Fertilizer and Lime Spreader SERIAL __________________ WORK ORDER ___________...

Страница 2: ......

Страница 8: ......

Страница 12: ......

Страница 13: ...Fertilizer and Lime Spreader Safety...

Страница 17: ...S 4 PTO SAFETY DECAL...

Страница 18: ...S 5 LUG NUT DECAL MAXIMUM LOADED SPEED MAKE SURE TO CHECK LUG NUTS DAILY CAUTION WARNING DO NOT EXCEED 25 MPH...

Страница 19: ...S 6 HYDRAULIC SYSTEM DECAL...

Страница 20: ...S 7 ROTATING CHAIN WARNING ROTATING SPINNERS WARNING...

Страница 21: ...PTO Shaft Adjustment And Maintenance...

Страница 24: ......

Страница 25: ...Section 1 Basic Information...

Страница 26: ...1 1 6PT FSS...

Страница 27: ...1 2...

Страница 29: ...Section 2 PTO Drive Spinners...

Страница 33: ...2 4...

Страница 36: ...2 7 Hydraulic Cylinder Engagement Assembly...

Страница 38: ......

Страница 39: ...PTF 71 2 RZ PTO Drive Spinner Gear Case Assembly and Parts List...

Страница 43: ...Section 3 Full Press Wheel Drive Assembly...

Страница 44: ...3 1...

Страница 47: ...3 4...

Страница 48: ...3 5...

Страница 49: ...3 6 Hydraulic Cylinder Engagement Assembly...

Страница 51: ...PTF 71 2 RZ FP Full Press Wheel Drive Spinner Gear Case Assembly and Parts List...

Страница 55: ...Section 4 Press Wheel for Plug to Tractor Hydraulic Spinners...

Страница 58: ...4 3...

Страница 61: ...4 6 Hydraulic Cylinder Engagement Assembly...

Страница 63: ...Section 5 Hydraulic Spinners...

Страница 64: ...5 1...

Страница 67: ...5 4...

Страница 68: ...5 5...

Страница 74: ......

Страница 75: ...Section 6 Flow Divider Assembly...

Страница 76: ......

Страница 77: ...5 4...

Страница 79: ...Section 7 Rigid Axle Assembly...

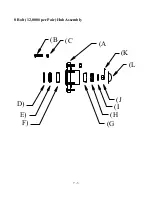

Страница 80: ...7 1 6 Bolt 7 000 per Pair Hub Assembly J I H G A F E C B D L K...

Страница 82: ...7 3 8 Bolt 12 000 per Pair Hub Assembly J I H G A F E C B D L K...

Страница 85: ...Section 8 Basic Set Up Operation...

Страница 88: ...8 3...

Страница 90: ......

Страница 91: ...Section 9 Maintenance Troubleshooting...

Страница 97: ...Section 10 Spread Pattern...

Страница 101: ...10 4 Data Recording...

Страница 102: ...10 5 Data Recording Unacceptable Pattern Acceptable Pattern...

Страница 104: ...10 7 Acceptable Pattern Using a 3 Pass Switchback Driving Method...

Страница 106: ...10 9 Notes...