9 - 3

Troubleshooting Procedures

The following investigation recommendations are given you to assist in simple repairs. To

effectively troubleshoot these areas there are only two (2) special instruments that will probably

not be found in a mechanic's tool box - these are - 0-1500 RPM hand tach and a 0-3000 PSI

pressure gauge. These items can normally be purchased locally but if you have problems

obtaining these items they can be purchased from Chandler Equipment Co.

Description

Part Number

Digital Hand Tach (0-1500 RPM)

300-FT-033

Hydraulic Pressure Gauge (0-3000 PSI)

400-1-351

The trouble shooting program outlined following has been expressed as simply as possible

through the use of a manual but if any questions arise please do not hesitate to call. If, after all

investigations have been carried out relating to your problem, and the problem remains, contact

Chandler Equipment Co.

Problem I:

Spinner speed very slow even when not spreading or not at all.

Recommended Investigation:

A)

Basic Checks

1)

Check to be sure indicator on flow control valve is located in its proper location

(Refer to spinner speed and spread pattern instructions).

2)

Check to be sure there is sufficient oil in tank and there is no restriction of any

manner in line allowing oil flow from bottom of tank to pump.

3)

Check spinner shaft bearings for proper lubrication and wear.

4)

Check that keyways are properly in place on motor shafts.

If

everything is in order proceed to investigation procedure

B

.

B)

Remove spool cap (3-7) from flow control valve. Remove other spool cap. From either

side, push out spool and spring. Clean all items removed thoroughly and blow dry with

air hose. Blow out housing areas thoroughly from which parts were removed.

Reassembly:

1)

Replace spool from upper side of housing making sure hollow end goes in first. Spool

should slide freely.

2)

Insert spring from lower side of housing. Make sure end of spring goes up in hollow part

of spool.

3)

Replace lower spool cap making sure spring sits in recessed area of spool cap.

4)

Replace upper spool cap.

If

problem has not been eliminated, continue to investigation procedure

C

.

Содержание PT-6 FSS

Страница 1: ...Model PT 6 FSS Fertilizer and Lime Spreader SERIAL __________________ WORK ORDER ___________...

Страница 2: ......

Страница 8: ......

Страница 12: ......

Страница 13: ...Fertilizer and Lime Spreader Safety...

Страница 17: ...S 4 PTO SAFETY DECAL...

Страница 18: ...S 5 LUG NUT DECAL MAXIMUM LOADED SPEED MAKE SURE TO CHECK LUG NUTS DAILY CAUTION WARNING DO NOT EXCEED 25 MPH...

Страница 19: ...S 6 HYDRAULIC SYSTEM DECAL...

Страница 20: ...S 7 ROTATING CHAIN WARNING ROTATING SPINNERS WARNING...

Страница 21: ...PTO Shaft Adjustment And Maintenance...

Страница 24: ......

Страница 25: ...Section 1 Basic Information...

Страница 26: ...1 1 6PT FSS...

Страница 27: ...1 2...

Страница 29: ...Section 2 PTO Drive Spinners...

Страница 33: ...2 4...

Страница 36: ...2 7 Hydraulic Cylinder Engagement Assembly...

Страница 38: ......

Страница 39: ...PTF 71 2 RZ PTO Drive Spinner Gear Case Assembly and Parts List...

Страница 43: ...Section 3 Full Press Wheel Drive Assembly...

Страница 44: ...3 1...

Страница 47: ...3 4...

Страница 48: ...3 5...

Страница 49: ...3 6 Hydraulic Cylinder Engagement Assembly...

Страница 51: ...PTF 71 2 RZ FP Full Press Wheel Drive Spinner Gear Case Assembly and Parts List...

Страница 55: ...Section 4 Press Wheel for Plug to Tractor Hydraulic Spinners...

Страница 58: ...4 3...

Страница 61: ...4 6 Hydraulic Cylinder Engagement Assembly...

Страница 63: ...Section 5 Hydraulic Spinners...

Страница 64: ...5 1...

Страница 67: ...5 4...

Страница 68: ...5 5...

Страница 74: ......

Страница 75: ...Section 6 Flow Divider Assembly...

Страница 76: ......

Страница 77: ...5 4...

Страница 79: ...Section 7 Rigid Axle Assembly...

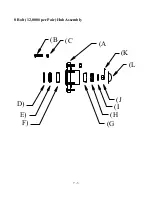

Страница 80: ...7 1 6 Bolt 7 000 per Pair Hub Assembly J I H G A F E C B D L K...

Страница 82: ...7 3 8 Bolt 12 000 per Pair Hub Assembly J I H G A F E C B D L K...

Страница 85: ...Section 8 Basic Set Up Operation...

Страница 88: ...8 3...

Страница 90: ......

Страница 91: ...Section 9 Maintenance Troubleshooting...

Страница 97: ...Section 10 Spread Pattern...

Страница 101: ...10 4 Data Recording...

Страница 102: ...10 5 Data Recording Unacceptable Pattern Acceptable Pattern...

Страница 104: ...10 7 Acceptable Pattern Using a 3 Pass Switchback Driving Method...

Страница 106: ...10 9 Notes...