SPANNTOP [nova] – Disassembly

WARNING!

Danger of injury due to vertical suspended

spindle!

Bending into the machine work are when as-

sembling overhead can cause severe head in-

juries.

Secure components prior to overhead as-

sembly.

For assembly on a vertically suspended

spindle always use a suitable mounting aid.

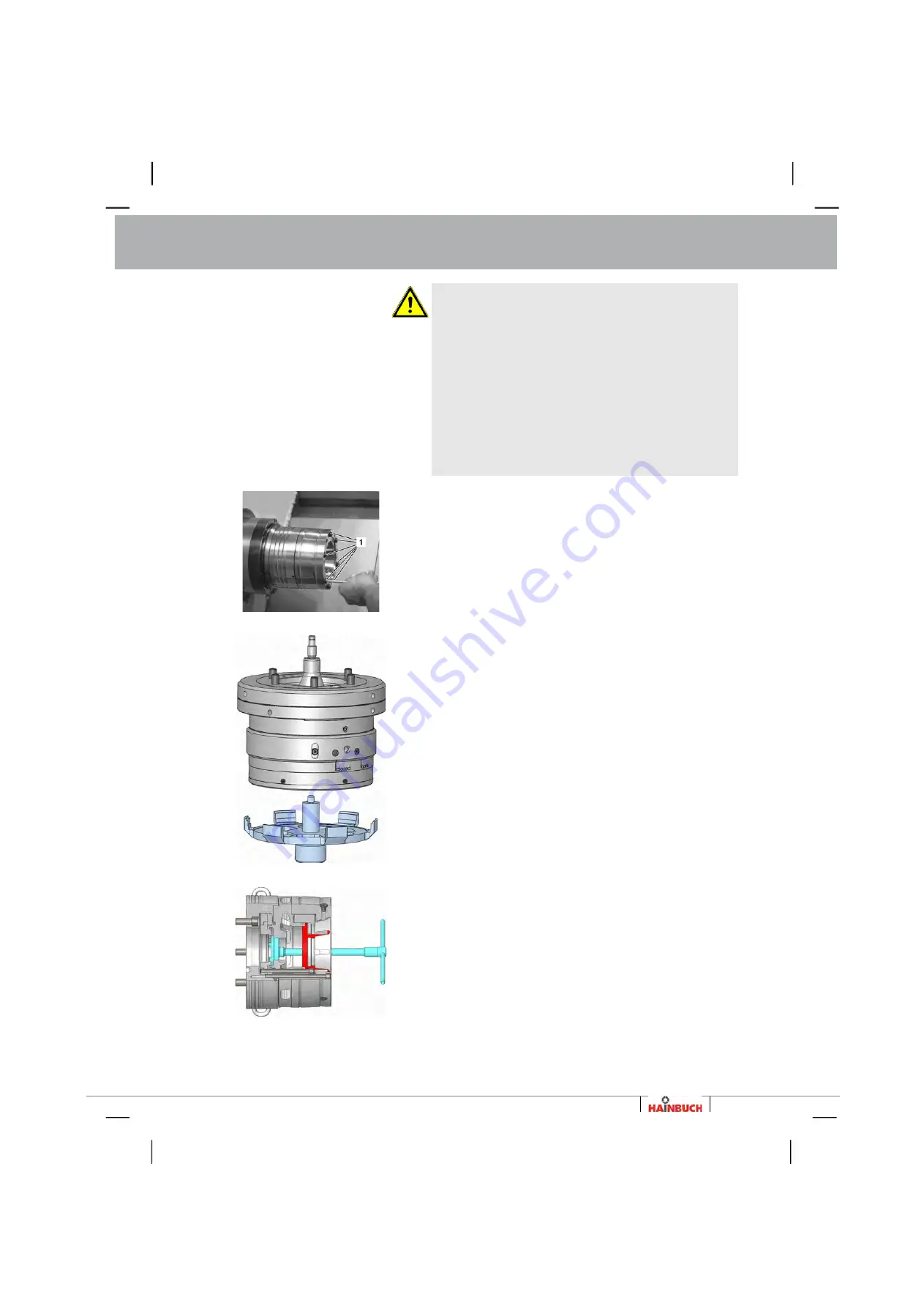

Fig. 79

4. Loosen all cylindrical screws [1] with an allen

wrench and unscrew them from the clamping unit.

Fig. 80

5. Vertically suspended disassembly:

Place the assembly plate [illustration is symbolic]

on the tool turret.

In jog mode, move the spindle slowly and care-

fully downward until it touches the clamping unit.

Fig. 81

6. Insert wrench [if necessary through the assembly

plate] into the clamping unit, so that the wrench

engages in the grooves of the adapter.

7. Use the wrench to unscrew the adapter from the

drawtube of the machine, via the adapter thread.

In this process ensure that the drawtube adapter

does not tilt.

93

Содержание SPANNTOP NOVA

Страница 1: ...Installation manual SPANNTOP nova combi pull back combi deadlength modular...

Страница 44: ...SPANNTOP nova Technical data 3 2 1 Clamping force diagram size 32 Fig 5 44 Order hotline 49 7144 907 333...

Страница 45: ...SPANNTOP nova Technical data 3 2 2 Clamping force diagram size 42 52 Fig 6 Order hotline 49 7144 907 333 45...

Страница 46: ...SPANNTOP nova Technical data 3 2 3 Clamping force diagram size 65 80 Fig 7 46 Order hotline 49 7144 907 333...

Страница 47: ...SPANNTOP nova Technical data 3 2 4 Clamping force diagram size 100 125 Fig 8 Order hotline 49 7144 907 333 47...

Страница 48: ...SPANNTOP nova Technical data 3 2 5 Clamping force diagram size 140 160 Fig 9 48 Order hotline 49 7144 907 333...

Страница 110: ...SPANNTOP nova Appendix 110 Order hotline 49 7144 907 333...