Three Piece High Pressure Ball Valves

–

H25 Valves Series

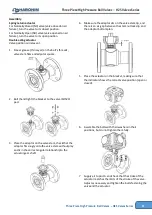

Three Piece High Pressure Ball Valves

–

H25 Valves Series

2

1.

General

This Installation, Operating & Maintenance manual represents the instructions required

for safe use of Habonim ball valve. The manual relates to reduce and full bore valves.

Before using any of these series valves, read the entire IOM carefully and make sure

everything is clear. Where in doubt, please consult with Habonim engineering team.

2.

Sil

Under severe operating conditions inspection should be more frequently; detected

defects should be repaired promptly. Severe operating conditions can be defined as:

•

Application temperature less or above than specified on the valve tag label

•

Flow velocity higher than 5 m/sec for liquids, and 200 m/sec for gaseous

•

Acidic media PH < 5 or alkaline media PH > 9

Habonim recommend a proof test interval of 12 months; in case of Fail to Open ESD system, a partial

stroke is acceptable to confirm that the installation is functioning properly.

For ESD systems with a Fail-To-Close demand, it is necessary to plan a system shut-down; de-energize

the system and inspect the valve turning to its fully closed position.

It is essential to log-in the following parameters on site QA records

as a proof for preserving SIL capabilities: date, hour, name and signature of the responsible

engineer, air pressure on site, time to close the valve, time to open the valve.

The combined corrosion and erosion allowance for the valve body wall thickness is 1 mm. When this

allowance has been eroded or corroded, mechanically removed or otherwise, the valve should no

longer be used. Inspect the valve wall thickness every time the valve is maintained.

The estimated mean time to repair (MTTR) a valve, i.e. time net (line draining or cooling down time

excluded from the valve MTTR) of replacing old valve with a new one is 60 minutes. Maintenance

team must read and understand the Habonim product IOM before starting the operation. In case of

a doubt please consult the Habonim engineering team.

When a valve has been repaired or any maintenance was performed, check the valve for proper

function (proof testing). Any failures affecting functional safety should be reported to the Habonim

factory.

Proof test and maintenance

During a proof test operation, all the inner soft parts (seats, seals, stem packing and bearings) to

be examine and replaced (only Habonim OEM repair kits can be used!) in interval less than 5 years

to claim the valve assembly

"

as-good-as-

new “

.

Habonim recommend valve full maintenance operation every

500,000 cycles or 5 years

, whichever

comes first.

Client should consult the Habonim factory to obtain the product assessment, FMEDA report, and

other associated statistical data to satisfy SIL level