Three Piece High Pressure Ball Valves

–

H25 Valves Series

Three Piece High Pressure Ball Valves

–

H25 Valves Series

15

1.

General

•

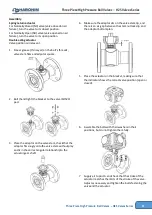

It is strongly recommended to review both the disassembly and assembly chapters before getting

started.

•

For any discrepancies, please contact Habonim.

2.

Disassembly

•

Cycle the valve with the line pressure fully relieved before attempting to remove the valve from the

pipeline, to ensure pressure has also been discharged from the valve cavity

.

•

Set the valve to open position.

•

Remove the dowel pins.

•

Carefully remove the ends from the valve body.

•

Remove and discard the seats, body seals and all the valve parts.

•

Set the valve to close position.

•

Support the ball to prevent it from falling out of the valve body and set the ball aside in a clean

secure area for reuse.

•

Remove stem nut and all the stem assembly components.

•

Place all the removed components, in a clean and secure area.

•

Push the stem down into the body and remove it.

•

Discard the stem thrust seals, care taken not to scratch or nick the stem bore area of the body.

•

Clean the stem and the stem bore area.