Three Piece High Pressure Ball Valves

–

H25 Valves Series

Three Piece High Pressure Ball Valves

–

H25 Valves Series

9

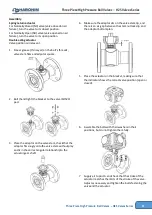

8.

Maintenance

HABONIM valves have a long and reliable life, and maintenance is seldom required. When maintenance is

necessary, valves can be refurbished on site.

To extend valve performance and reduce possible plant problems, the following procedures should be followed:

7.1.

If leakage around the stem is noticed, check the stem nut torque according to value in Table 1 in the

Disassembly and assembly manual. If the leak continues, tighten the gland nut about a 1/4-turn as a

routine maintenance procedure. This will compensate for any wear or settling of the gland packing.

Caution: Excessive tightening of the stem nut can result in accelerated seal wear

and high valve operating torque.

7.2.

It is

strongly recommended

to tighten the

stem nut torque according to value in Table 1 in the

Disassembly and assembly manual every 15,000 cycles.

7.3.

If the valve is removed from the line and disassembled, replacement of all seats and seals is recommended

using the appropriate Habonim Repair kit. Examine all metallic sealing surfaces such as ball, stem, and the

surfaces on the end connectors that contact the seats for wear, corrosion or damage.

7.4.

Only Habonim authorized spare parts should be used. Default repair kit parts from Habonim can be found

at "components & materials" in Habonim catalog.

7.5.

In addition to repair kits, other spare parts are available from Habonim, such as stem, glands, bolts, screws

and nuts.

7.6.

Should additional parts be required, it is recommended that the complete valve be replaced.

7.7.

When ordering repair kits, please provide the valve size and full figure number code and series, engraved

on the valve ID tag.