Three Piece High Pressure Ball Valves

–

H25 Valves Series

Three Piece High Pressure Ball Valves

–

H25 Valves Series

8

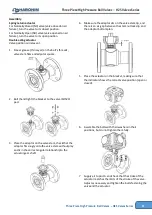

7.

Operating Instructions

Habonim Valves provide tight shut off when used under normal conditions and in accordance with Habonim

’

s

published pressure/temperature chart.

If these valves are used in a partially open (throttled) position, seat life may be reduced. Consult with Habonim for

the proper seat material selection.

On manual operated valves, the valve operation is done by turning the valve handle 90° clockwise to open

(handle is parallel to flow line), and 90° counter clockwise to close (handle is perpendicular to flow line).

For unidirectional designed valves; a flow arrow indicates the flow direction of the valve for proper installation. A

silicone-based lubricant is applied to assist valve break in. The lubricant, if unacceptable, may be removed by a

solvent wash.

If a shut-off valve is installed for end of line service, it must be ensured that it is closed with a blind end

connection and the valve is secured against being opened unintentionally.

WARNING: Never look into the valve bore while the valve is in a flow line. Pressure and

fluids could escape from the valve causing harm or injury.

To prevent leakage, malfunctions resulting from internal wear or seal degradation, the

user must establish a preventive maintenance and inspection program. This program

must include:

1.

Inspection of parts to detect loss of wall thickness which may result in decreased

pressure capacity (see Para. 3 for acceptable reduction of wall thickness).

2.

Routine replacement of seals and inspection for proper operation (See Para. 7 for

maintenance instructions).

Valve operating torques, as published in the Habonim literature, are the normal

expected maximum break-out torques. These torques have been confirmed by

laboratory testing of each valve under controlled conditions. Highly viscous or

abrasive media, frequency of operation and temperature fluctuations could cause an

increase in valve torque.