Three Piece High Pressure Ball Valves

–

H25 Valves Series

Three Piece High Pressure Ball Valves

–

H25 Valves Series

12

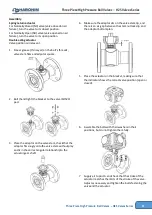

8.

Carry out an operating check with the air pressure

connected to port A, in the case of a spring-return

actuator, or to port B for a double-acting actuator.

Ensure that opening and closing of the valve is complete,

i.e. the ball and valve ports are correctly aligned when the

valve is open. If the valve opening is not complete, align

the ball port position by turning the actuator adjustment

screws. New actuator adjustment screws are locked in

place

by using Loctite221, any change of screws position, must

be repeated with renewal of the glue over the screws

thread.

9.

Tighten all bracket bolts with suitable spanner.

10.

Hold the adaptor and lift it up and down (up to 1 mm

recess), make sure no tension exerted on the valve

stem by the adaptor.

11.

Connect the air hose or solenoid valve to the actuator.

Warning

–

Moving parts can cause serious damage to

employees. Remove hands and tools from the

bracket area and from the valve port area.

12.

Pressurize the actuator (port A) with air pressure

adjusted to the actuator spring configuration.

13.

Inspect valve and actuator quarter turn free

movement.

14.

Depressurize the actuator and inspect safe return to

start position.