trailing edge down) and 8 units aircraft nose-down (8

±

1° tab trailing

edge up).

Mechanical stops limit elevator trim wheel movement to 6.6 turns

from each stop. A shear rivet installed in the cockpit portion of the

system prevents application of excessive force by shearing at

approximately 31 pounds of force.

(3) Electric Pitch Trim:

Located on the pilot’s flight panel, the PITCH TRIM ENG / DISENG

switch engages or disengages the electric pitch trim. Pitch trim is

also engaged whenever the autopilot is engaged. With electric pitch

trim engaged (amber DISEN switch legend extinguished), pitch trim

can be adjusted through use of a split-half pitch trim switch

(sometimes referred to as a “beep” switch) installed on the outboard

grip of each control wheel. Switch positions are labeled NOSE

DOWN and NOSE UP. Inadvertent actuation of pitch trim, including

runaway, is minimized through the split-half switch design. In order

for the pitch trim to be actuated, both halves of the switch must be

simultaneously moved in the same direction.

Movement of the electric pitch trim switch to NOSE DOWN or NOSE

UP actuates the autopilot elevator trim servo. The trim servo is

connected to the manual trim control wheel set by a chain. The

chain-driven movement of the manual trim control wheel set in turn

positions the elevator trim tabs.

The electric pitch trim is normally checked by the flight crew on the

first flight of the day, during the Before Starting Engines checklist. A

check usually consists of running the elevator trim fully up, then fully

down, using normal methods, i.e., using both halves of the switch

simultaneously. This is followed by attempting to run the pitch trim

using each half of the switch alone. Any movement resulting from

using either half of the switch alone indicates a malfunction that

should be corrected before flight. The check is concluded by setting

pitch trim for the takeoff Center of Gravity (CG) condition as

determined using the Airplane Flight Manual.

(4) Elevator Trim Tab Actuator Heat System:

Electrically-heated elevator trim tab actuators are incorporated on

airplanes SN 1380 and subsequent and SN 1000 through 1379

having ASC 342. These actuators are designed to alleviate frozen or

stiff trim tab actuators possible in extreme cold temperatures. The

system receives power from Phase C of the Left Main AC bus.

Operation of the system is automatic and transparent to the flight

crew.

F. Angle-of-Attack / Stall Barrier System:

(See Figure 4, Figure 10 and Figure 11.)

While in flight, the Angle-of-Attack (AOA) system monitors aircraft AOA to

provide warnings of an approaching stall. If AOA continues to increase

toward aerodynamic stall, the system applies a nose down control input

through the stall barrier system.

The AOA / stall barrier system consists of the following units and

components:

OPERATING MANUAL

PRODUCTION AIRCRAFT SYSTEMS

2A-27-00

Page 10

January 31/02

Revision 6

Содержание IV

Страница 3: ...GIV Flight Controls Aerodynamic Axes Figure 1 OPERATING MANUAL 2A 27 00 Page 3 4 January 31 02 ...

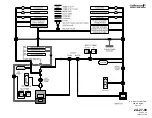

Страница 4: ...GIV Flight Controls Fluid Power Diagram Figure 2 OPERATING MANUAL 2A 27 00 Page 5 6 January 31 02 ...

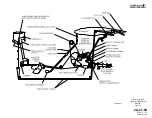

Страница 16: ...Stall Barrier Angle of Attack Wiring Schematic Figure 4 OPERATING MANUAL 2A 27 00 Page 19 20 January 31 02 ...

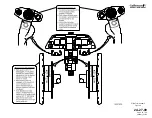

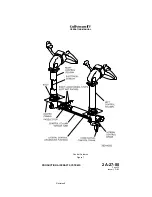

Страница 17: ...Pitch Trim Controls Figure 5 OPERATING MANUAL 2A 27 00 Page 21 22 January 31 02 ...

Страница 32: ...Rudder Pedals Forward Linkage Figure 13 OPERATING MANUAL 2A 27 00 Page 39 40 January 31 02 ...

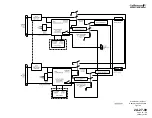

Страница 50: ...Flaps Simplified Block Diagram Figure 18 OPERATING MANUAL 2A 27 00 Page 61 62 January 31 02 ...

Страница 51: ...Flaps Simplified Electrical Diagram Figure 19 OPERATING MANUAL 2A 27 00 Page 63 64 January 31 02 ...

Страница 65: ...Spoiler Speed Brake Controls and Indications Figure 23 OPERATING MANUAL 2A 27 00 Page 79 80 January 31 02 ...

Страница 66: ...Ground Spoiler Controls and Indications Figure 24 OPERATING MANUAL 2A 27 00 Page 81 82 January 31 02 ...