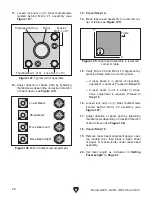

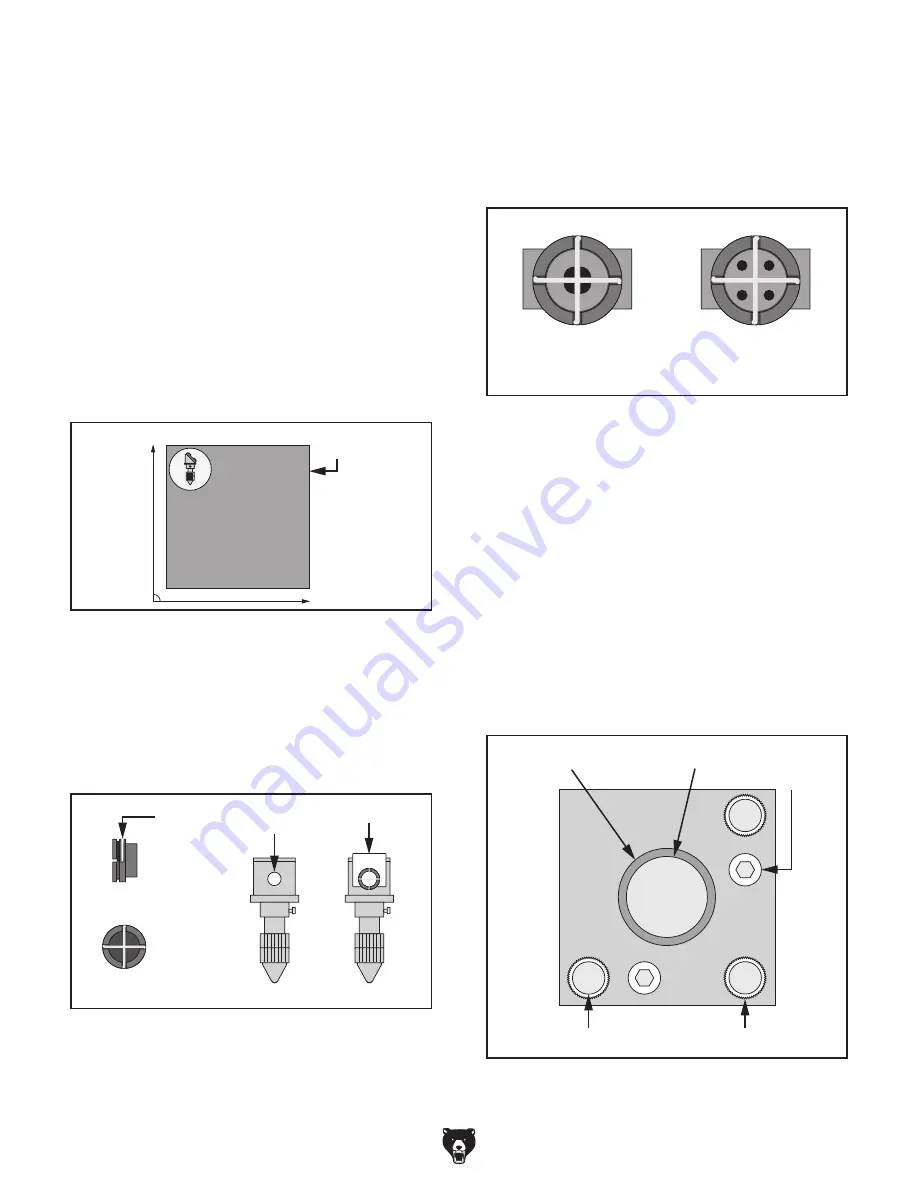

Laser Head Assembly

Front

View

Side

View

Paper

Slot

Mirror #3

Beam Inlet

Paper

Figure 107. Laser beam alignment gauge

installed in beam inlet.

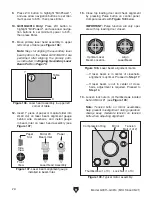

Optimal Laser

Beam Location

Align

Laser Beam

Figure 108. Laser beam alignment marks.

X

Y

Table

Figure 106. Laser head assembly in upper left

corner of table.

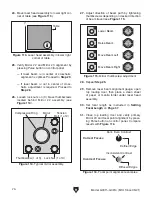

Mirror

Tension

Bolt (1 of 2)

Compression Ring

Thumbscrew (1 of 3)

Lock Nut (1 of 3)

Figure 109. Typical mirror assembly.

-72-

Model G0911–G0914 (Mfd. Since 05/21)

12.

Insert 1" piece of paper or manila folder into

small slot on laser beam alignment gauge

behind wire crosshairs, and install gauge

in beam inlet on laser head assembly (see

Figure 107).

13.

Close top loading door and check alignment

by pressing Pulse button on control panel.

Compare results with

Figure 108 below.

IMPORTANT: Pulse function will only oper-

ate with top loading door closed.

— If laser beam is in center of crosshairs,

alignment is optimal. Proceed to

Step 17.

— If laser beam is not in center of cross-

hairs, adjustment is required. Proceed to

Step 14.

14. Loosen lock nuts on (3) thumbscrews located

behind Mirror #1 (see

Figure 109).

Note: Tension bolts on mirror assemblies

help prevent misalignment during operation.

Always keep moderate tension on tension

bolts when adjusting alignment.

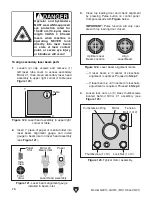

9.

Press Z/U button to highlight "MinPower1",

and use arrow navigation buttons to set mini-

mum power to 50%, then press Enter.

10. G0913/G0914 Only:

Press Z/U button to

highlight "MinPower2", and use arrow naviga-

tion buttons to set minimum power to 50%,

then press Enter.

11.

Move primary laser head assembly to upper

left corner of table (see

Figure 106).

Note:

Steps for aligning the secondary laser

beam path on the Model G0913/G0914 are

performed after aligning the primary path,

as instructed in

Aligning Secondary Laser

Beam Path on Page 75.

Содержание G0911

Страница 100: ......