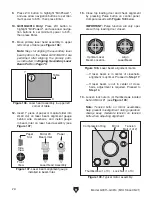

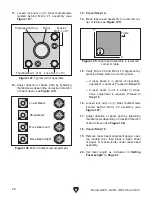

Figure 95. Location of water chiller ports.

Figure 94. Leadscrew nut measurement.

-66-

Model G0911–G0914 (Mfd. Since 05/21)

Removing/Installing

Laser Tube(s)

Leveling Table

Each CO

2

gas-filled laser tube is supported by

two soft-mount saddles and straps. Each tube has

four connection points: two for water inlet/outlet

hoses, and two for electrical connections.

The following procedure includes steps required

for the purpose of long-term storage or machine

shipping. If the laser tube has reached the end

of its service life and will be discarded, the tube

should be placed in a container and tagged for

appropriate disposal.

Note: Laser tube removal/installation is the same

on primary and secondary laser tubes.

Items Needed

Qty

Hex Wrenches 2.5, 3mm ..............................1 Ea.

Phillips Head Screwdriver #2 ............................. 1

Utility Knife ......................................................... 1

Bucket ................................................................. 1

Container (for Removed Laser Tube) ................. 1

Isopropyl Alcohol ................................ As Needed

Removing Laser Tube

1. DISCONNECT MACHINE AND AUXILIARY

SYSTEMS FROM POWER!

2. Open laser tube access door.

3.

Disconnect water hose(s) at INLET port(s) of

water chiller, and place end(s) into bucket to

collect water runoff

(see

Figure 95

).

The Model G0911–G0914 table may slowly twist

or drop over time, causing inadequate workpiece

cutting and variations in engraving quality.

Items Needed

Qty

Protective Gloves................................................ 1

Precision Ruler ................................................... 1

To level table:

1. DISCONNECT MACHINE FROM POWER!

2. Verify machine is level (see Leveling on

Page 22).

3. Open front access door and lower side

access door, then measure distance of each

leadscrew nut from bottom of cabinet (see

Figure 94

).

— If measured distance is the same for all

leadscrews, no adjustments are required.

— If measured distance is not the same for

all leadscrews, proceed to

Step 4.

INLET

OUTLET

4. Release Z-axis belt tension on leadscrew(s)

requiring adjustment (see

Step 6

of

Z-Axis

Belts Adjustment

on

Page 61)

.

5.

Grasp irregular leadscrew(s) by hand and

rotate to raise or lower table until

distance

measured in

Step 2

is the same for all

leadscrews

.

6.

Tension Z-axis synchronous belt (see

Step 6

of

Z-Axis Belts Adjustment on Page 61).

Area of

Measurement

Содержание G0911

Страница 100: ......