Model G0853 (Mfd. Since 07/18)

-71-

5. Load workpiece onto table saw in rear mount-

ing position, shown in

Figure 140 on Page

70. If necessary, use edge shoe to secure

workpiece to sliding table.

6. Take all necessary safety precautions, con-

nect saw to power, then perform cutting

operation.

Crosscutting Smaller Panels

1. DISCONNECT MACHINE FROM POWER!

2. Install crosscut fence in rear mounting loca-

tion shown in

Figure 140 and secure in place.

3. Perform Steps 3–4 in Crosscutting Full-

Size Panels.

4. Set either flip stop to the desired width of cut.

Note: Extend the crosscut fence slide if the

workpiece is more than 75

7

⁄

8

".

Crosscutting Using Rip Fence as

Cut-Off Gauge

1. DISCONNECT MACHINE FROM POWER!

2. Install crosscut fence in rear position of

crosscut table, as illustrated in

Figure 141 on

Page 70, and secure in place.

3. Perform Steps 3–4 in Crosscutting Full-

Size Panels.

4. Set rip fence to desired width of cut.

5. Slide leading end of rip fence behind front

edge of blade (see

Figure 143 for an

example).

IMPORTANT:

This step is critical to reducing

the risk of blade binding and kickback.

6. Load workpiece onto table saw and against

rip fence. The setup should look similar to

Figure 141 on Page 70.

7. Take all necessary safety precautions, con-

nect saw to power, then perform cutting

operation.

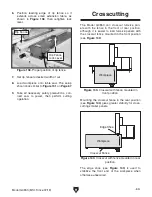

Figure 143. Example photo of correct rip fence

position when using it as a cut-off gauge

(blade guard removed for clarity).

Rip Fence

Front Edge

of Blade

Leading Edge

of Rip Fence