Model G0825 (Mfd. Since 02/17)

-31-

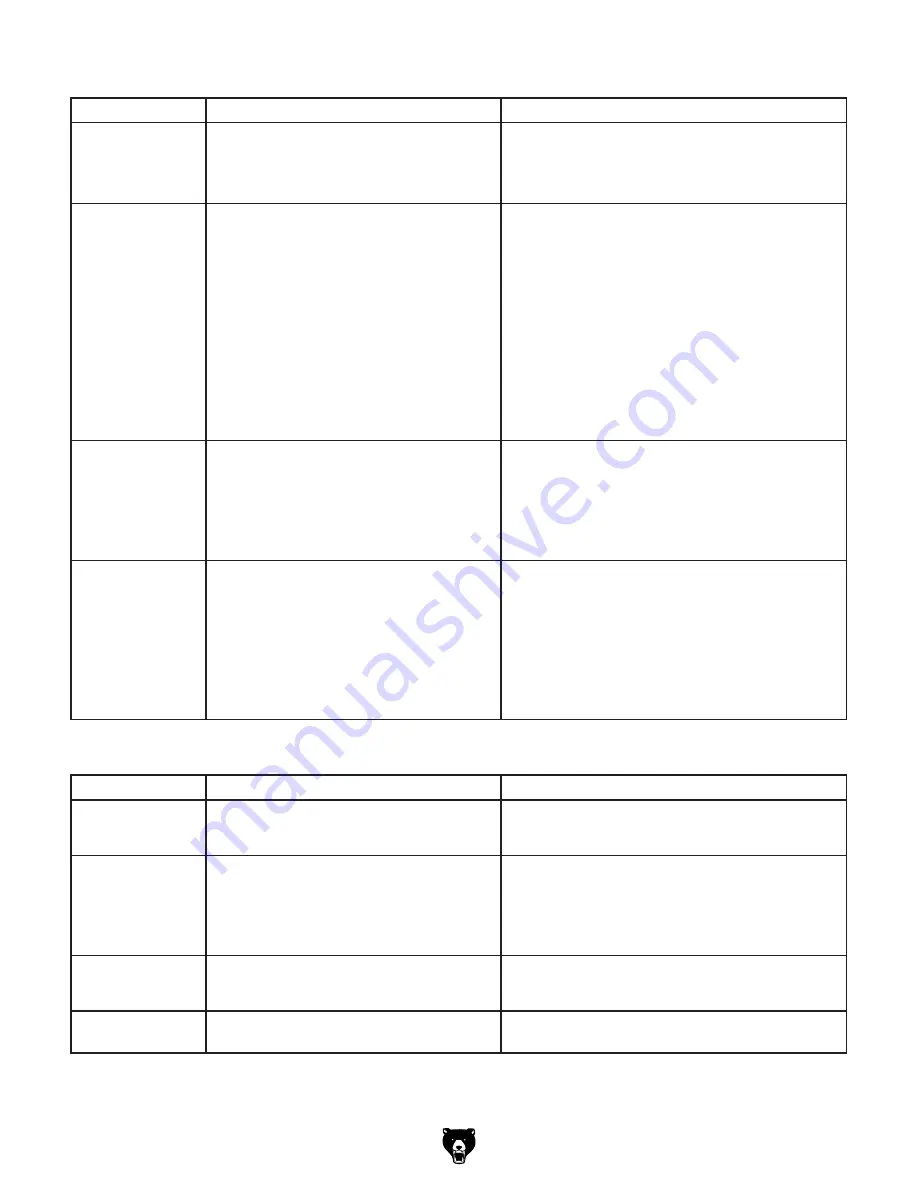

Glue Spindle

Symptom

Possible Cause

Possible Solution

Glue spindle does

not rotate.

1. Motor does not run.

2. Too much oil added to glue spindle.

3. Gear teeth stripped/broken.

4. Gear set screw loose.

1. Refer to

Page 30.

2. Remove oil from gear.

3. Inspect/replace gear.

4. Tighten gear set screw.

Glue spindle does

not dispense

enough glue.

1. Glue flow out of adjustment.

2. Glue not fully melted, temperature setting

too low.

3. Glue not fully melted, heater rods not

working correctly.

4. Glue spindle not making full contact with

edgebanding.

5. Obstruction in glue channel.

6. Burnt glue on glue spindle.

7. Glue pot thermometer not accurate.

1. Properly adjust glue flow dial.

2. Adjust glue pot temperature according to glue

manufacturer's directions; confirm glue temperature

on control panel digital readout.

3. Inspect heater rod connections, tighten; test heater

rod amperage and replace if necessary.

4. Ensure glue pot is filled (

Page 18); adjust glue flow

rate.

5. Remove obstruction from glue channel.

6. Remove burnt glue from glue spindle.

7. Inspect temperature sensor connections and wires

for damage/wear; repair/replace if necessary.

Glue not fully melted

in glue pot.

1. Glue pot still heating.

2. Glue pot temperature is set too low.

3. Heater rods at fault.

1. Wait until glue reaches working temperature.

2. Set glue pot temperature according to glue

manufacturer's directions; confirm glue temperature

on control panel digital readout.

3. Inspect heater rod connections, tighten; test heater

rod amperage and replace if necessary.

Glue only adheres

to part of edge tape.

1. Operator not exerting enough force against

workpiece.

2. Glue spindle not making full contact with

edgebanding.

3. Outfeed pressure roller not making full

contact with workpiece.

4. Workpiece too wide, glue scraper tension

not adjusted properly.

1. Apply adequate pressure when moving workpiece

along outfeed roller.

2. Ensure glue pot is filled (

Page 18); adjust glue flow

rate.

3. Apply adequate pressure when moving workpiece

along outfeed roller.

4. Adjust glue scraper tension (

Page 19).

Edgebanding Results

Symptom

Possible Cause

Possible Solution

Edgebanding moves

up or down relative

to workpiece.

1. Infeed height guide not set properly.

1. Adjust infeed guide (

Page ???).

Too much/

not enough

edgebanding left on

top or bottom.

1. Infeed height guide not set properly.

2. Guide plate not set properly.

3. Excess glue build up on base plate.

1. Adjust infeed guide (

Page ???).

2. Adjust guide plate for each workpiece thickness

(

Page ???).

3. Properly clean edgebander before each use (

Page

29).

Scrape marks

on face of

edgebanding.

1. Debris/sharp edges/burrs/extra glue

obstructing path of edgebanding.`

1. Inspect entire path of edgebanding; clean away

debris; sand/file sharp edges/burrs.

Scrape marks on

face of workpiece.

1. Guide plate has debris/sharp edges/extra

glue embedded.

1. Thoroughly clean guide plate surface.

Содержание G0825

Страница 44: ......