25

VersiVent Energy Recovery Ventilator

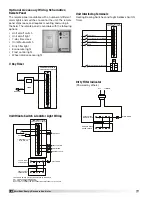

Supply Fan (Plenum Type)

The unit contains one plenum supply fan located on

the end of the unit opposite the outdoor air intake and

may optionally have a relief air blower which is referred

to as an exhaust blower in this document. Efficient fan

performance can be maintained by having the correct

offset.

Start-Up Components

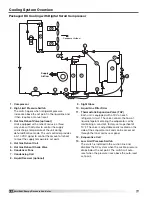

Energy Wheel

The energy wheel is installed in the unit’s airstream with

one half of the wheel in the intake airstream and one

half in the return airstream. Air leakage between the two

airstreams has to be kept to a minimum and the wheel

has air seals that must be adjusted for that purpose.

The seals must be adjusted at time of start-up.

Drive Belt

Inspect the drive belt. Make sure the belt rides smoothly

in the pulley and around the outside of the wheel. Note

the directional arrow and data information shown in the

image.

Adjust the Air Seals

The first step in wheel seal adjustment is to make sure

the unit power supply is locked

out. Disconnect the wiring to

the wheel module and pull

the wheel cassette out of the

cabinet on its tracks. Large

cassettes are not removable.

Then slowly rotate the wheel by

hand to make sure there is no

binding or misalignment. The

wheel should rotate smoothly

and should not bind.

There is a perimeter seal

located around the outside of

the wheel and a diameter seal

across the face of the wheel on

both sides. Check to make sure

that all air seals are secure and

in good condition.

Adjust the air seals by loosening all the air seal retaining

screws on the bearing support (see image for reference).

Using a piece of paper as a feeler gauge, adjust the

seals so they almost touch the face of the wheel while

tugging slightly on the paper. When the wheel is rotated,

there should be a slight tug on the paper. Tighten the

screws, repeat the steps on the other set of seals.

Push the wheel cassette back into the unit and plug

in the power connector. Turn the main power supply

back on and then observe the operation of the wheel by

opening the wheel access door slightly. Remove filters if

necessary to observe the wheel.

Label showing

cassette serial number

and date code

Bearing Support

Drive Pulley

Adjustable Air

Seals

Drive Belt

Bearing Support Bar

Showing air seal assembly

Retaining

Screws

CAUTION

When operating conditions of the fan are to be

changed (speed, pressure, temperature, etc.), consult

manufacturer to determine if the unit can operate

safely at the new conditions.

Inlet

Cone

Offset

Wheel

Unit

Fan

Offset

(inches)

Tolerance

(inches)

VER-45

QEP-15

5

±

1

⁄

8

QEP-18

6

3

⁄

8

±

1

⁄

8

VER-65

QEP-18

6

3

⁄

8

±

1

⁄

8

QEP-20

7

±

3

⁄

16

VER-90

QEP-20

7

±

3

⁄

16

QEP-24

8

5

⁄

8

±

1

⁄

4

Offset:

Proper offset, or overlap, is

adjusted by loosening the wheel hub

from the shaft and moving the wheel

to the desired position along the shaft.

The transition between the inlet cone

and the wheel should

be as shown; there is

a smooth feel to the

profile when moving

one component to the

other.

The unit contains two forward-curved exhaust fans

located on each side of the unit. These forward-curved

fans should be checked for free rotation. If any binding

occurs, check for concealed damage and foreign

objects in the fan housing.

Fan Performance Modifications

Due to job specification revisions, it may be necessary

to adjust or change the sheave or pulley to obtain the

desired airflow at the time of installation. The start-up

technician must check blower amperage to ensure that

the amperage listed on the motor nameplate is not

exceeded. Amperage to be tested with access doors

closed and ductwork installed.

Fan Belt Drives

The fan belt drive components, when supplied by

manufacturer, have been carefully selected for the

unit’s specific operating condition. Utilizing different

components than those supplied could result in unsafe

operating conditions which may cause personal injury or

failure of the following components:

• Fan Shaft

• Bearings

• Motor

• Fan Wheel

• Belt

Exhaust Fan