22

VersiVent Energy Recovery Ventilator

Pre Start-Up Checklist

Every installation requires a comprehensive start-up

to ensure proper operation of the unit. As part of that

process, the following checklist must be completed and

information recorded. Starting up the unit in accordance

with this checklist will not only ensure proper operation,

but will also provide valuable information to personnel

performing future maintenance. Should an issue arise

which requires factory assistance, this completed

document will allow unit experts to provide quicker

resolve. Qualified personnel should perform start-up to

ensure safe and proper practices are followed.

Unit Model No. ____________________________________

Unit Serial No. _____________________________________

Heat Pump Model No. ______________________________

Energy Wheel Serial Number ________________________

Compressor 1 Model No ____________________________

Compressor 2 Model No. ___________________________

Start-Up Date _____________________________________

Start-Up Personnel Name __________________________

Start-Up Company _________________________________

Phone Number ____________________________________

Pre Start-Up Checklist

o

Disconnect and lock-out all power switches.

o

Remove any foreign objects that are located in the

energy recovery unit.

o

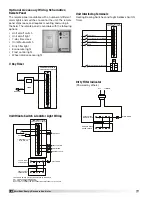

Check all fasteners, set-screws, and locking collars

on the fans, bearings, drives, motor bases and

accessories for tightness.

o

Check fan rotation.

o

Rotate the fan wheels and energy recovery wheels

by hand and ensure no parts are rubbing.

o

Check the fan belt drives for proper alignment and

tension.

o

Filters can load up with dirt during building

construction. Replace any dirty pleated filters and

clean the aluminum mesh filters in the intake hood.

o

Verify that non-motorized dampers open and close

properly.

o

Check the tightness of all electrical wiring

connections.

o

Verify control wire gauge.

o

Verify diameter seal settings on the energy recovery

wheel.

o

Verify proper drain trap installation.

o

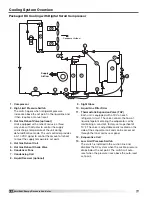

Check condensing fans for any damage or

misalignment. Spin the blades and make sure they

don’t contact any parts and are free-turning without

any resistance.

o

Look over the piping system. Inspect for oil at all

tubing connections. Oil typically highlights a leak in

the system.

o

Inspect all coils within the unit. Fins may get

damaged in transit or during construction. Carefully

straighten fins with a fin comb.

o

If there is an indirect gas-fired furnace in this unit,

refer to the manual provided with this unit for Pre-

Start-Up information.

o

This unit contains a crankcase heater for each

compressor which needs power supplied to it

24 hours prior to start-up. If start-up is scheduled

in 24 hours, unlock the disconnect power and

energize unit.

Line Voltage. Check at unit disconnect.

L1-L2

Volts

L2-L3

Volts

L1-L3

Volts

Motor Amp Draw

Supply Motor Amps

L1

Amps

L2

Amps

L3

Amps

Exhaust Motor Amps

L1

Amps

L2

Amps

L3

Amps

Fan RPM

Correct fan rotation direction?

Supply Fan

RPM

Supply Fan

Yes / No

Measured Airflow

CFM

Exhaust Fan

RPM

Exhaust Fan

Yes / No

Measured Airflow

CFM

Energy Wheel Motor

L1

Amps

L2

Amps

L3

Amps

Start-Up Checklist