Slip two 5/32" [4mm] wheel collars onto the pushrod. Bend

the pushrod 90 degrees up at the mark. From the bend

measure up 3/8" [9.5mm]. Then, cut off the excess pushrod

wire. Install the wire into the hole in the servo arm using a

nylon FasLink.

❏

19. Re-center the other elevator. Bend the pushrod as

shown above to mate it with the first pushrod. Place the two

wheel collars as shown; put a drop of Great Planes Pro

Threadlocker

™

in the wheel collar screw hole and tighten the

wheel collar to the wires with a 6-32 x 1/4" [6-32 x 6mm]

socket head cap screw in each wheel collar.

You should now have all of the servo installation complete.

This leaves only the installation of the receiver/battery tray

into the fuselage. With all of the room in the fuselage you are

probably wondering why we don’t have the battery and

receiver mounted on a tray with the servos. The battery and

receiver need to be mounted where we have them in order

to achieve the proper balance without having to add weight

to the tail. This airplane has very clean lines and there is no

place we could have easily added tail weight without having

to stick lead to the tail or the fuselage. Though it is a bit

inconvenient, this installation utilizing a removable rear

former allows you to balance the plane without added

weight. Also, the removable front former allows access for

servicing the fuel tank.

❏

1. If the servos are not still connected to the receiver,

reconnect them. Plug the battery into the switch. Slide a

piece of heat shrink tubing over the connection or tape the

connections together to prevent them from coming loose in

flight. In addition to your servo connections, plug two 12"

extensions into the proper channels on your receiver for the

aileron and flaps. Mark the end of each extension for easy

identification of the flap and aileron.

❏

2. Install the receiver/battery tray using the two 4-40 x

5/8" [4-40 x 16mm] phillips pan head screws. In order to do

this you will probably need to disconnect the pushrods and

possibly remove the screws from the rear former. It really

depends on how large your hands are. Again, we understand

this is a bit inconvenient but once installed, you should not

have to remove the tray very often.

❏

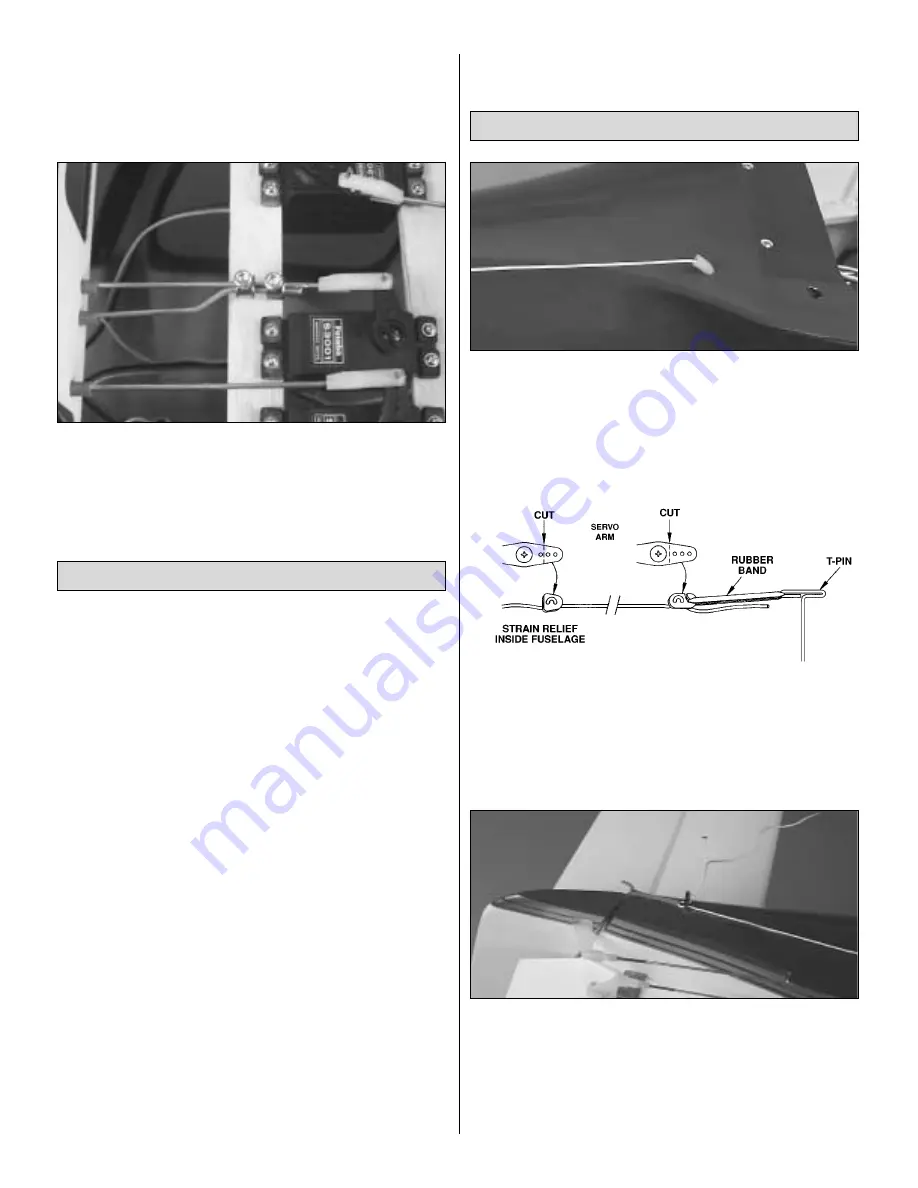

1. Here is a suggested method for installing the receiver

antenna. Other methods may also be acceptable. Drill a

5/32" [4mm] hole in the bottom of the fuselage. Be sure that

this hole does not interfere with the location of the receiver

tray. Insert a 3/4" length of fuel tubing into the hole. This will

protect the wire from being cut by the edge of the fiberglass.

❏

2. With a leftover servo arm, make a strain relief for the

antenna as shown. Install one arm onto the antenna wire,

sliding it onto the wire to within a few inches of the receiver.

Insert the antenna through the hole / fuel tubing in the

fuselage. Guiding the wire to the aft of the fuselage, install

the other arm onto the end of the wire as shown.

❏

3. The rubber band needs to be placed over an

attachment point at the end of the fuselage. We drilled a

5/64" [2mm] hole at the rear of the fuselage, tapped the hole

with a 2-56 tap and made a hook from a small length of

2-56 threaded rod. You might also consider installing a T-pin

in the bottom of the rudder or you can tape the rubber band

to the bottom of the fuselage.

Receiver Antenna Routing

Install the Receiver & Battery

28

Содержание Lancair ES

Страница 40: ......