❏

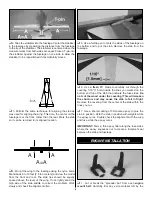

7. Cut two holes in the belly pan to access the bolts.

Measure and place a mark 4-3/4" [123mm] forward of the aft

edge on the belly pan. Place two marks 1-7/8" [47mm] from

the centerline. Drill two 1/2" [13mm] holes at the crossing of

these two lines to access the wing bolts.

By moving the position of the clevis at the control horn

toward the outermost hole, you will decrease the amount of

throw of the control surface. Moving it toward the control

surface will increase the amount of throw. If these

adjustments don’t accomplish the job, you may need to work

with a combination of adjustments by also repositioning the

pushrod at the servo end. Moving the pushrod towards the

center of the servo horn will decrease the control surface

throw – outward will increase it.

Note:

Throws are measured at the widest part of the

elevators, rudder and ailerons. We recommend the following

control surface throws as a starting point:

Elevator

5/16" [8mm] Up

7/16" [11mm] Down

Rudder

2" [50mm] Right

2" [50mm] Left

Ailerons

3/8" [9.5mm] Up

3/8" [9.5mm] Down

These control throws are recommended for normal flying. If

you are planning on performing extreme “3D” aerobatics,

see the section on “Advanced Aerobatics” for the

recommended control throws, notes on using computer

radios and details on performing some maneuvers

associated with this exciting new form of aerobatics.

One leading cause of crashes is flying an airplane with its

control throws set differently from those recommended in

the instructions. The Great Planes AccuThrow

™

lets you

quickly and easily measure actual throws first, so you can

make necessary corrections before you fly. Large, no-slip

rubber feet provide a firm grip on covered surfaces without

denting or marring the finish. Spring tension holds

AccuThrow’s plastic ruler steady by each control surface.

Curved to match control motions, the ruler provides exact

readings in both standard or metric measurements.

GPMR2405.

Make sure the control surfaces move in the proper direction

as illustrated in the following sketch:

Note:

This section is

VERY

important and must

NOT

be

omitted! A model that is not properly balanced will be

unstable and possibly unflyable.

❏

1. The balance point (C.G.) is located 9-1/4" [236mm]

forward from the trailing edge of the wing. Balance your

Giles using a Great Planes C.G. Machine

™

Airplane

Balancer (GPMR2400) for the most accurate results. This is

the balance point at which your model should balance for

your first flights. After initial trim flights and when you

become more acquainted with your Giles, you may wish to

experiment by shifting the balance up to 3/8" [9.5mm]

forward or backward to change its flying characteristics.

Moving the balance forward may improve the smoothness

and stability, but the model may then require more speed for

takeoff and may become more difficult to slow for landing.

Moving the balance aft makes the model more agile with a

lighter, snappier “feel” and often improves knife-edge

BALANCE YOUR MODEL

4-CHANNEL

TRANSMITTER

4-CHANNEL

TRANSMITTER

4-CHANNEL

TRANSMITTER

4-CHANNEL RADIO SET-UP

(STANDARD MODE 2)

TRANSMITTER

4-CHANNEL

ELEVATOR MOVES UP

RIGHT AILERON MOVES UP

LEFT AILERON MOVES DOWN

RUDDER MOVES RIGHT

CARBURETOR WIDE OPEN

Control Surface Throws

Control Throw Adjustment

20