❏

3. Test fit the stopper into the

fuel tank.

The seam

around the tank should be vertical. By holding the tank up to

the light you will be able to see where the vent tube is, in

relation to the top of the tank. If necessary, bend the vent

tube to position it about 1/8" [3mm] below the top of the tank.

When satisfied with the fit, make sure the stopper is fully

seated in the fuel tank. Tighten the stopper screw until the

plastic cap is indented about 1/16" [1.5mm]. Doing so will

lock the stopper into position. Check the clunk and pickup

tube to make sure they move freely in the tank without

binding or stopping.

❏

4. Cut a piece of 1/4" [6mm] thick foam rubber to 5-1/2"

x 2" [14mm x 50mm]. Place the foam onto the tank floor

inside the fuselage. Before installing the tank, make sure the

bent vent tube points toward the top of the fuselage. Apply

a bead of 100% silicone sealer around the sides of the

rubber stopper and the front edge of the fuel tank. Insert the

tank fully into the tank compartment while working the

stopper into the hole in the firewall. The silicone will seal the

opening and help hold the tank in position after it has cured.

Use two or three #64 rubber bands at the aft end of the tank

to secure it to the tank floor.

❏

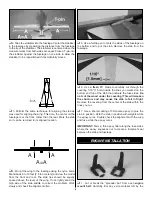

1. Locate the two

aluminum main gear

and secure them

to the fuselage using six

#6 washers

and six

6-32 x 5/8"

socket head cap screws.

Use thread locking compound on

the screws to prevent them from loosening during flight.

❏ ❏

2. Press the

landing gear cover

onto the bolts to transfer

their locations onto the cover. Remove the cover, and

remove the material from the locations to allow the cover to

set flush with the fuselage. A 1/4" [6mm] drill bit works well

for this step.

❏ ❏

3. Glue the landing gear cover into position using

medium CA or 6-minute epoxy. (You did use thread locking

compound on those six bolts?)

❏ ❏

4. Position the

wheel pant

onto the landing gear. The

bottom of the gear will be flush with the pant locks as shown

in the photo. Use a felt-tip marker to transfer the locations of

the holes in the landing gear onto the wheel pants.

❏ ❏

5. Drill the locations marked onto the wheel pants.

Use a 1/8" [3mm] drill bit for the two smaller holes. The

larger hole is drilled using a 1/2" [13mm] drill bit.

MAIN LANDING GEAR INSTALLATION

11