13

12

Grange Machinery Ltd.

Sproatley Grange

Hull

HU11 4PT

M: 07918 515385

T: 01482 815711

E: [email protected]

W: www.grangemachinery.co.uk

Grange Machinery Ltd.

Sproatley Grange

Hull

HU11 4PT

M: 07918 515385

T: 01482 815711

E: [email protected]

W: www.grangemachinery.co.uk

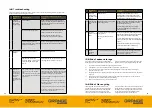

5.1 Rear attachments

The rear clevis hitch and linkage arms are designed for coupling up and towing

only 2nd stage cultivation / seeding equipment which complements the use of the

Grange 3m LDT in tillage practices.

If you have any queries on the specification of equipment which can be coupled or

hitched up to the Grange 3m LDT please contact the team at Grange Machinery Ltd

for further advice.

LINKAGE OPTIONS FOR TRAILED IMPLEMENT

i.

Cat III Clevis Hitch

ii.

Cat III lower link hooks to attach to linkage frame of trailed implement

iii.

Scharmuller Piton Pin Hitch 45mm

iv.

Scharmuller K80 Ball Hitch

v.

Braking: Where a hydraulic braking supply is required for 2nd stage cultivation/seeding

equipment this facility will be incorporated into the auxiliary valve assembly on the rear.

(Ref Section 8.0, component information).

COMPLETE LEG ASSEMBLY

i.

Top Leg –c/w 3 x adjustable heights

ii.

Bottom leg. c/w shear bolt and

pivot bolt.

iii.

Points – Wing width range of 40mm –

110mm c/w fastening bolt.

DEPTH ADJUSTMENT SPACERS FOR

LIFT / LOWER HYDRAULIC RAMS

Black - 38 mm

Yellow - 19 mm

Green -13 mm

Red -10 mm

Blue -07 mm

6.0 Lifting and slinging of Grange 3m LDT

The Grange 3m LDT range includes two lifting eyes (Ref fig 1.0) for use with

appropriate and compliant shackles and webbing or chains. Ensure that the lifting

equipment has the required lift capacity and is operated by trained and authorised

personnel. Ensure that there is adequate space in the immediate area and check for

overhead obstacles such as electric power cables. For further guidance on safe lifting

techniques please refer to HSE guidance at;

http://www.hse.gov.uk/work-

equipment-machinery/planning-organising-lifting-operations.htm

FIG 1.0: LIFTING AND SLINGING POINTS