23

22

Grange Machinery Ltd.

Sproatley Grange

Hull

HU11 4PT

M: 07918 515385

T: 01482 815711

E: [email protected]

W: www.grangemachinery.co.uk

Grange Machinery Ltd.

Sproatley Grange

Hull

HU11 4PT

M: 07918 515385

T: 01482 815711

E: [email protected]

W: www.grangemachinery.co.uk

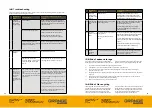

FIG 4.0 CALCULATION TO DETERMINE TRACTOR FRONT BALLAST REQUIREMENT

Key

Definition

Where to find values

T

E

[kg]

Mass of un-laden tractor

1

T

F

[kg]

Front axle load of un-laden tractor

1

T

R

[kg]

Rear axle load of un-laden tractor

1

I

R

[kg]

Combined mass of rear-mounted implement / rear

ballast

2

I

F

[kg]

Combined mass of front mounted implement /

front ballast

To be calculated

a

[m]

Distance from centre of gravity for combined front

mounted implement / front ballast to front axle

centre.

1/ FBD

b

[m]

Tractor wheelbase

1 / 3

c

[m]

Distance from rear axle centre to centre of lower

link balls.

1 / 3

d

[m]

Distance from centre of lower link balls to centre

of gravity for combined rear-mounted implement /

rear ballast.

0.57m. (Design specification of

Grange 3m LDT).

1

See instruction handbook of the tractor. Check

maximum front axle permissible load.

2

The mass of the Grange 3m LDT

without a 2nd

stage cultivation/seeding equipment coupled to the

clevis hitch or linkage arm assembly is

1250kg.

When connecting any other equipment to the 3m

LDT the drawbar / hitch mass (Kg) of the 2nd stage

cultivation/seeding equipment must be added that

of the Grange 3m LDT [1250Kg] to establish an

overall kilogram loading on the tractor hitch, value

IR.

Please note that the maximum mass of seed or

other materials held in a hopper in the 2nd stage

cultivation/seeding equipment needs to be included

in the overall value of

IR’

FBD

[m]

FBD: Front balance distance

Measurement of the centre of gravity of the tractor

front weight assembly or centre of gravity of front

mounted implement to the tractor front axle.

Refer to operator’s manual for front mounted

implements to verify the position of the centre

of gravity.

3

To be measured

FIG 5.0 CORRECT LINKAGE CONFIGURATION IN WORKING POSITION

10.0 Setting up machine for work

When setting up the tractor for connection to the Grange 3m LDT, firstly adjust the

lower link check chains to reduce the lateral sway as much as possible (ideally less

than 20mm). Ensure that the linkage balls are not corroded and can turn on the pins.

The correct top link setting is important to ensure the Grange 3m LDT is safe and

efficient in operation, ref Fig 5.0. Fig 6.0 shows a correctly configured Grange 3m LDT

coupled up to 2nd stage cultivation / seeding equipment via the link arm hitch.

The lower link arms should remain locked in position during all work and transport

mode operations. Minimal adjustment of the link arms can provide additional

clearance over obstacles. Activate the auxiliary hydraulics to raise the cutting discs

and legs to their top position to clear any surface obstacles. This setting then

provides a consistent coupling height for 2nd stage cultivation/seeding equipment

connected to the clevis hitch.