25

24

Grange Machinery Ltd.

Sproatley Grange

Hull

HU11 4PT

M: 07918 515385

T: 01482 815711

E: [email protected]

W: www.grangemachinery.co.uk

Grange Machinery Ltd.

Sproatley Grange

Hull

HU11 4PT

M: 07918 515385

T: 01482 815711

E: [email protected]

W: www.grangemachinery.co.uk

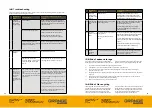

FIG 6.0 3M LDT IN COUPLING POSITION WITH 2ND STAGE

CULTIVATION EQUIPMENT IN WORKING MODE

Refer to the tractor’s operators manual for safe use of the coupling

controls. Keep all personnel clear of the zone between the tractor rear

linkage and the Grange 3m LDT when undertaking coupling procedures.

Ensure that the tractor is safely coupled to the 3m LDT before raising

the implement and engaging transmission.

When connecting 2nd stage cultivation/seeding equipment; activate the

tractor auxiliary hydraulics to lift the Grange 3m LDT main beam and

cutting discs to the top of their travel. This provides suitable clearance

to lower the main frame on the tractors three point linkage to couple

up with the Grange 3m LDT with the 2nd stage cultivation/seeding

equipment using either clevis or link arm attachment.

Ensure that the 2nd stage cultivation/seeding equipment is safely

attached the rear of the Grange 3m LDT along with hydraulic and

electrical connections.

10.1 Clevis hitch

The mass of the rear clevis hitch on the Grange 3m LDT equipment

has a mass of 45kg. Therefore the safe working procedure is to put

the coupling pin through the clevis hitch and secure in place, with a

washer and nut and bolt. Use a workshop crane or other approved

lifting systems to take the weight before removing the locating pin.

Readjust and relocate securing pin with the appropriate lynch pin

before releasing from the lifting equipment. Fig 7.0 and 8.0 illustrates

the component and securing method.

TOWING PIN AND ALSO USED FOR

ATTACHING THE LIFTING EQUIPMENT

Connect the hydraulic couplings to the tractor double acting services.

Be-aware of the hazards associated with hydraulic hoses under pressure.

FIG 10.0 LINK ARM HITCH REMOVED FROM

REAR OF GRANGE 3M LDT

10.2 link arm hitch

The mass of the rear link arm hitch has a mass of approximately 100kg.

Removal of the rear link arm hitch will require the use of mechanical

handling equipment with adequate lift capacity and counterbalance,

with the use of compliant strops or chains and lifting hook. Fig 9.0

identifies the lifting point, which is at located at the components centre

of gravity and Fig 10.0 illustrates the Grange 3m LDT once the link arm

hitch has been removed.

FIG 9.0 SECURING POINT FOR LINK ARM

HITCH REMOVAL

FIG 7.0 ATTACHMENT PIN

FIG 8.0 LYNCH PIN FOR SECURING

ATTACHMENT PIN