37

36

Grange Machinery Ltd.

Sproatley Grange

Hull

HU11 4PT

M: 07918 515385

T: 01482 815711

E: [email protected]

W: www.grangemachinery.co.uk

Grange Machinery Ltd.

Sproatley Grange

Hull

HU11 4PT

M: 07918 515385

T: 01482 815711

E: [email protected]

W: www.grangemachinery.co.uk

18.0 Warranty

The Grange Machinery Ltd. 3m Low Disturbance

Toolbar is covered for a period of 12 months from

the date of delivery to farm (which is recorded

on our files) against faulty components and/or

bad workmanship. All products are checked and

hydraulically tested prior to delivery/collection.

We cannot be responsible for claims arising from

ignorance, occurrences outside our control, such as

accidents, and malicious damage.

Warranty claims for damage during transport

Damage occurred during transit via an external

haulier must be reported immediately upon

unloading and signing for the item. The limit of our

liability to undertake repairs to products damaged

during transit is dependent on signing for any

damaged product upon delivery as “DAMAGED”.

Machines must return to Grange Machinery Ltd

to have any warranty work carried out. Grange

machinery Ltd genuine pars must be used to keep

warranty valid throughout use.

Any modification or tampering to the Grange 3m

LDT without prior consent from Grange Machinery

Ltd will invalidate the 12 month machine warranty.

The content of this operator manual are correct at

the time of print but may be subject to additions

or change at any time in the future. Replacement

operator manuals must be ordered in relation to the

model and serial number provided.

I

F

,min = (

I

R

x

(c+d))-(

T

F

x

b

)+(0,2

x

T

E

x

b)

a+

b

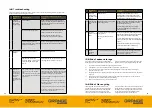

Appendix 1.0: Example calculations: Ref Fig 4.0

I

R

Please note these are indicative calculations

using industry examples for typical 200hp

tractor specifications. Due to the combination

of the Grange 3m LDT and 2nd stage cultivation/

seeding equipment the tractor machine

combination can become unstable. The following

expression can be applied for the calculation

of the minimum ballasting at the front (IF

min) which allows to have a load on the front

axle equal to 20% of the unladen mass of the

tractor. The operator of the Grange 3m LDT and

and coupled 2nd stage cultivation / seeding

equipment must input the relevant values for

the tractor and 2nd stage cultivation / seeding

equipment they are using. In addition variables

such as tractor tyre pressures also need to be

checked and set to suit operational conditions.

Key

Definition

Values inputted

T

E

[kg]

Mass of un-laden tractor

7300Kg

T

F

[kg]

Front axle load of un-laden tractor

2701Kg

T

R

[kg]

Rear axle load of un-laden tractor

4599Kg

I

R

[kg]

Combined mass of rear-mounted implement / rear

ballast (Grange 3m LDT)

1250kg

I

F

[kg]

Combined mass of front mounted implement /

rear ballast

See calculations below

a

[m]

Distance from centre of gravity for combined front

mounted implement / front ballast to front axle

centre.

1.48m

b

[m]

Tractor wheelbase

2.884m

c

[m]

Distance from rear axle centre to centre of lower

link balls.

1.1m

d

[m]

Distance from centre of lower link balls to centre

of gravity for combined rear-mounted implement /

rear ballast. (Grange 3m LDT)

0.57m

1.0

Example tractor specifications: Typical 200hp, including integral front linkage and

weight block with only the Grange 3m LDT attached;

IF (min) = (1250x(1.1+0.57)) – (2701x2.884) + (0.2x 7300 x 2.884) / 1.48 + 2.884

IF (min) = (1250x(1.67))-(7789)+(4210) / 4.364

IF (min) = - (minus) 342kg (e.g no front counterbalance required)

2.0

Example tractor specifications: Typical 200hp including integral front linkage and

weight block with the Grange 3m LDT attached and also a 2nd stage cultivation/

seeding equipment with a drawbar load of 2500kg. The clevis hitch on the Grange

3m LDT is located at approximately the same position as the units centre of gravity.

Therefore the

IR = ( 2500kg)

IF (min) = (3750x(1.1+0.57)) – (2701x2.884) + (0.2x 7300 x 2.884) / 1.48 + 2.884

IF (min) = (3750x (1.67))-(7789)+(4210) / 4.364

IF (min) = + 615 Kg (e.g 615kg of front counterbalance required on the tractor)