Conveyor belts

Page 42

5. Run the belt, and when distances D and

E are approximately the same increase

the length (A) again with the counted

number of turns.

6. Tighten both locknuts (1).

Checking belt tension

Check the correct belt tension.

If the belt tension is too high, extra stress is placed on the bearings in the magnet roller and return roller.

General rule, if the roller rotates continuously, the tension is as it must be.

First loosen the adjustment so far that the roller stops.

Then tighten the adjustment (equally on both sides) so that the roller rotates continuously, then the tension

is as it must be!

The recommended belt tension depends on operational circumstances.

In a light duty installation the belt will be tensioned no more than 0,5 - 1,0%.

If the tension of the belt is too high or too low, it must be adjusted:

1. Release belt tension so that the belt lies loosely on the rollers.

2. Tension the belt using the tensioner unit, until it is no longer loose.

3. Mark two stripes on the belt exactly 1000 mm apart.

4. If for example one wishes to tension the belt to a stretch factor of 0.5%, adjust the belt tensioner

until the distance between the two stripes is exactly 1005 mm.

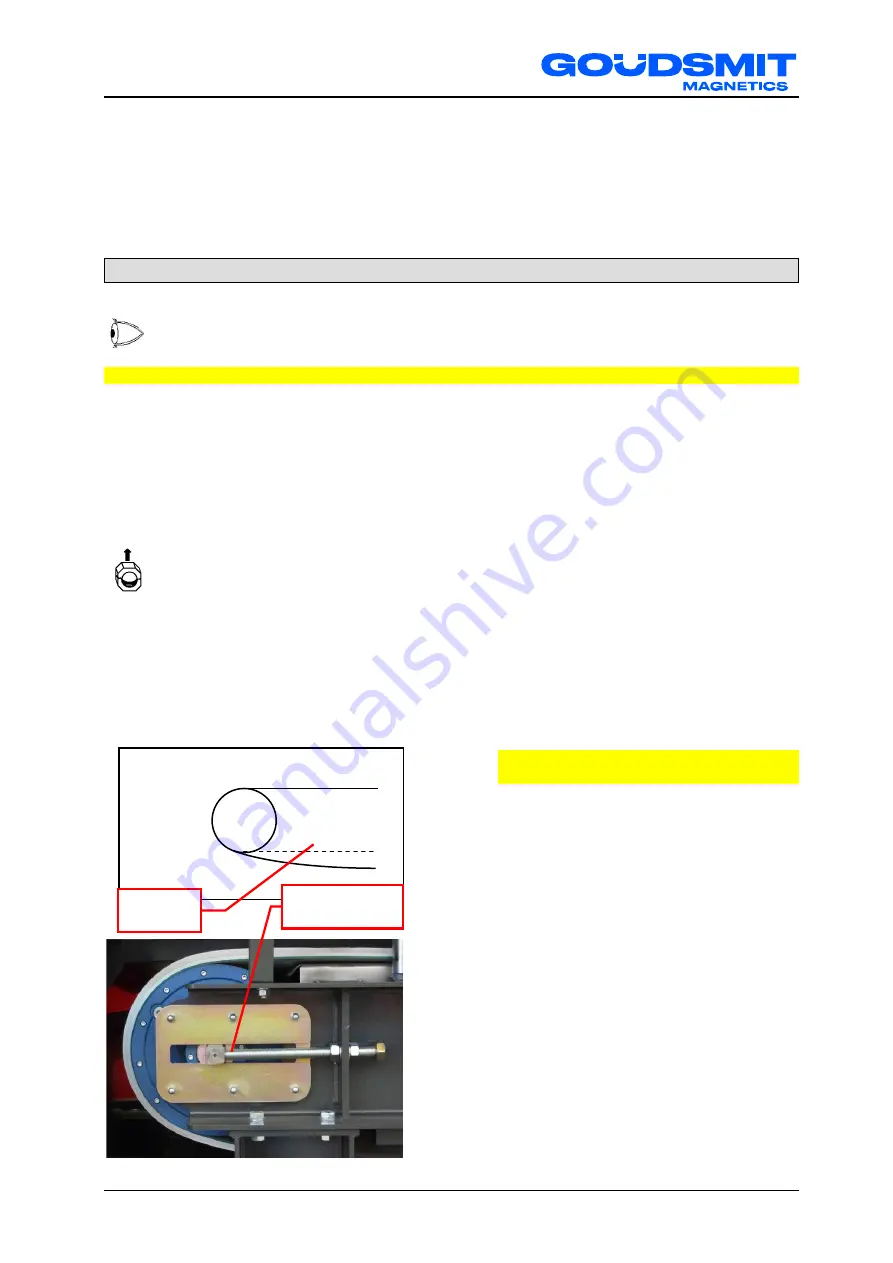

Attention: the belt must still sag after

tensioning!

To check

: take 2% of the distance between

the main rollers in mm as minimum sag.

Example: 1000 mm between rollers:

1000 x 0.02 = 20 mm sag

Belt sag

Belt tensioner