Operation Manual for ZBL-R620/R630 Rebar Locator

Caution:

During detection process, it is advised to implement a reset operation about every ten

minutes.

If test data is unreliable, implement reset, then re-test.

2.4 Choosing Scan Mode

ZBL-R630 Rebar Locator provides several scan and work modes, the user can select

the most suitable mode according to their requirements.

Measuring modes: general test, profile-scan, and grid-scan.

Press

【

Enter

】

key to access the highlight option

Caution: Each scan mode has corresponding parameter setting interface.

(Select the different mode to watch the corresponding video)

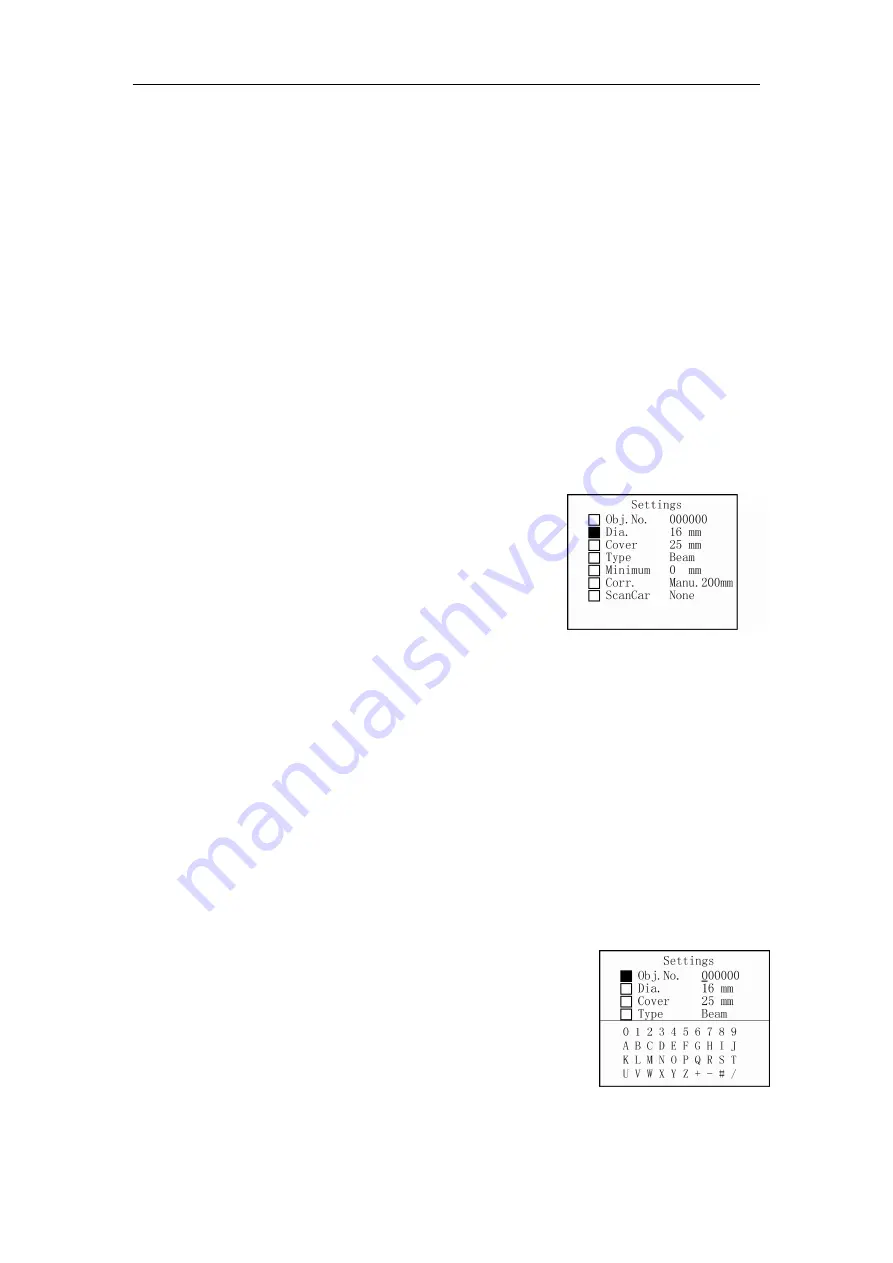

2.5 Parameter Settings (Fig. 2.5)

Set related parameters according to testing component situation, including object code,

diameter forecast, design thickness, component type, etc.

【↑

,

↓】

keys, move cursor;

【

Enter

】

key, access highlight option;

【

Back

】

key, save current parameter setting, return to

previous menu, and reset the system;

【

Menu

】

key, return to main menu interface.

Parameter amendment:

1) General situation

【↑

,

↓】

keys, select the parameter required;

【

Save

】

key, save current setting, return to parameter setting interface.

2) Object code settings

Select the “object code” option, the soft-keyboard will display.

Select the digit which requires modification

Press

【←

,

→】

keys, move the cursor to the digit which requires modification;

Press

【↓】

key, a cursor displays in the top-left corner of soft-keyboard;

Press

【

Back

】

key, return to parameter setting interface.

Select character

【↑

,

↓、←、→】

keys, move cursor to select character;

【

Enter

】

key, select the character at present cursor point,

and return to previous menu.

E.g. (shown in video)

Move the cursor to “general test” option, press

【

Enter

】

key to access parameter setting interface. (Fig. 2.6)

1) Object code -- Object code is composed of six characters; numbers, letters or

Fig. 2.5 General Test

Fig. 2.6 object code setting interface