82

Englis

h

12. Maintenance

The purpose of the maintenance program is to keep the equipment in good

working conditions and to achieve the maximum service life of it.

DANGER: Stop the engine before performing any maintenance.

If you need to start up the engine for any type of check, make sure that the area is

well ventilated. Exhaust gases contain poisonous carbon monoxide.

NOTE:

Use original GENERGY spare parts or proven quality components for

maintenance.

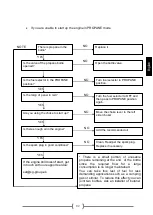

Maintenance schedule:

SERVICE

MAINTENANCE PERIODS

Engine oil

Check the level before each use. First oil change after 20 hours of

break-in. Subsequent oil changes every 100 hours of use.

Air filter

Check and clean every 50 hours. Replace when it begins to wear out.

Spark plug

Clean and adjust the electrode every 50 hours. Replace every

300hours or before if any damage is noticed.

Cleaning the fuel strainer

Every 300 hours or 1 year (whichever is first)

Engine valves*

Adjust every 500 hours*

Combustion chamber*

Clean every 500 hours*

Fuel filter and tank*

Clean every 500 hours*

Gasoline hose

Replace every two years or sooner if any wear is noticed*

NOTE:

Perform maintenance more frequently when the equipment is used in

places with a lot of dust or very high temperatures.

NOTE:

Services marked with an asterisk have to be performed by a

GENERGY service or qualified service center. Keep a receipt of the operations

carried out by the service center.

NOTE:

Lack of compliance with maintenance services will shorten the life of

the generator and produce malfunctions that will not be covered by the warranty.

Warranty will not be respected if the detailed maintenance plan is not observed,

except in case of authorization to skip a service by GENERGY or an authorized

GENERGY service.

Содержание 401173

Страница 2: ......

Страница 51: ......

Страница 100: ......

Страница 149: ...145 Português ...

Страница 150: ...146 Português POLIGONO INDUSTRIAL NEINVER CALAHORRA LA RIOJA CONTACTO INFORMAÇÕES INFO SG GROUP ES ...