—————— Instruction manual ——————

371

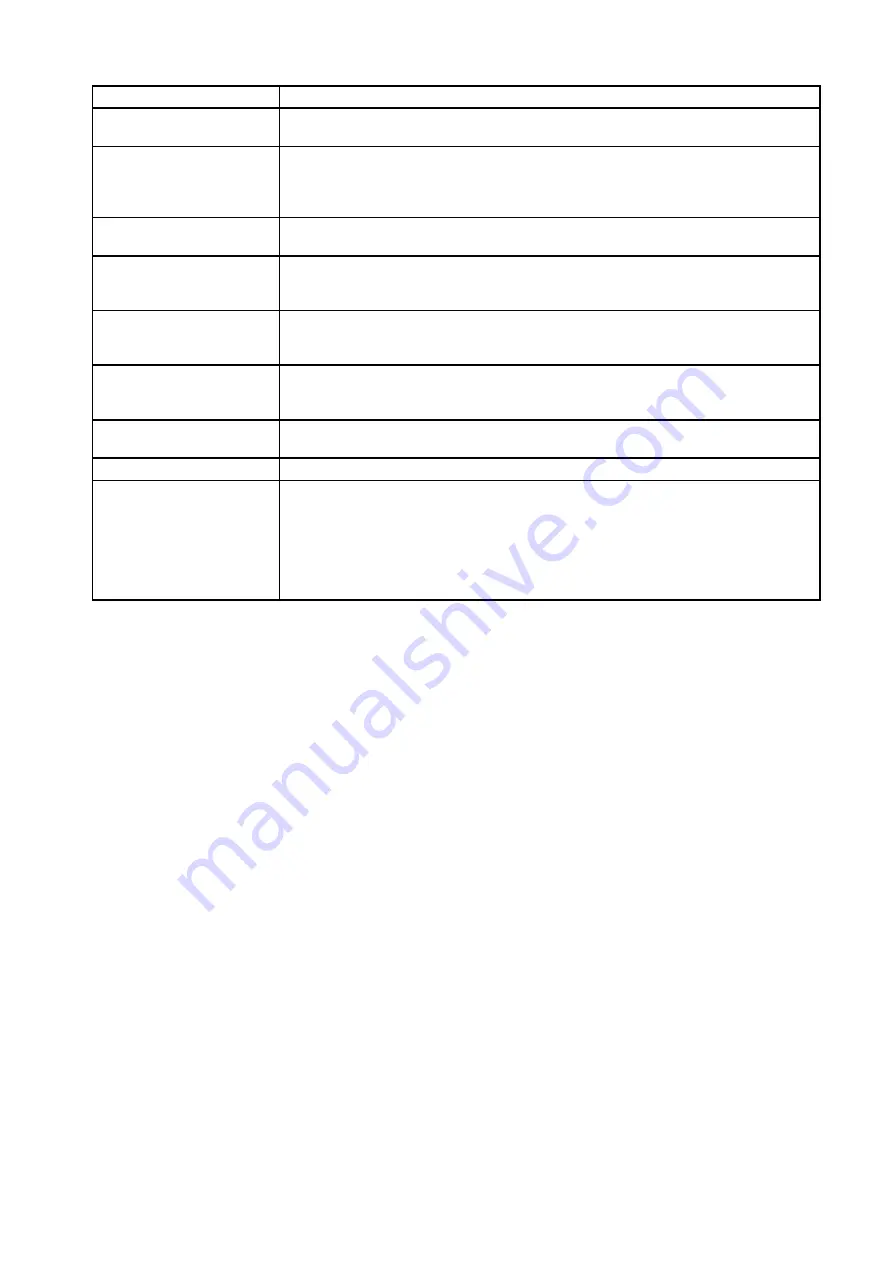

FAILURE

POSSIBLE CAUSES

The speed during acceleration

with max. current is not linear

• Reduce the

Speed I

and

Speed P

proportionally. If this does not lead to an improvement, optimize

the regulator (see chapter 5.3.6).

Speed oscillating

• Check

Speed P

and

Speed I

parameter

• If the operating point is in the field weak range, check the

Fld reg P gain

and

Fld reg I gain

parameters and eventually

Voltage P

and

Voltage I

parameters.

• Remedy: Optimize the regulator as previously described

Drive not reacting to adaptive

speed regulation

• Adaptive speed regulation not enabled.

Enable spd adap

= Enabled

Motor potentiometer function

not executed

• Function not enabled.

Enable motor pot

= Enabled

• With operation via the terminal strip:

Motor pot up

and/or

Motor pot down

were not assigned to

a digital input

Jog operation not possible

• A start command is still present

• Function not enabled.

Enable jog

= Enabled

• With operation via terminal strip:

Jog +

and/or

Jog -

were not assigned to a digital input.

Internal speed reference values

not carried out

• Function not enabled.

Enab multi spd

= Enabled

• With operation via terminal strip:

Speed sel 0, Speed sel 1

and

Speed sel 2

were not assigned

to a digital input.

Multi-Ramp function not

reacting

• Function not enabled.

Enab multi rmp

= Enabled

• With operation via terminal strip:

Ramp sel 0

and

Ramp sel 1

were not assigned to a digital input

Overload not possible

• Function not enabled.

Enable overload

= Enabled

The Current regulator selftune

procedure never finishes and

continues over and over again.

• Because of the motor inductance value, the routine is executing an endless loop. The inductance

value is cycling between two values without an evolution of the

algorithm.

• Solution procedure:

1) verify the two displayed inductance values

2) insert the average value as motor inductance during the autotuning.

If the procedure does not end, repeat step 1) and 2).

Содержание TPD32-EV-...-2B

Страница 1: ... Instruction manual Industrial Application DC drives TPD32 EV ...

Страница 62: ... TPD32 EV 62 10 mm 0 4 150 mm 6 150 mm 6 150 mm 6 10 mm 0 4 10 mm 0 4 50 mm 2 Figure 3 3 2 Mounting Clearance ...

Страница 372: ... TPD32 EV 372 9 BLOCK DIAGRAM 9 1 CONTROL BLOCK DIAGRAMS ...

Страница 373: ... Instruction manual 373 ...

Страница 374: ... TPD32 EV 374 ...

Страница 375: ... Instruction manual 375 ...

Страница 376: ... TPD32 EV 376 ...

Страница 377: ... Instruction manual 377 ...

Страница 378: ... TPD32 EV 378 ...

Страница 379: ... Instruction manual 379 ...

Страница 380: ... TPD32 EV 380 ...

Страница 381: ... Instruction manual 381 ...

Страница 382: ... TPD32 EV 382 ...

Страница 383: ... Instruction manual 383 ...

Страница 384: ... TPD32 EV 384 ...

Страница 385: ... Instruction manual 385 ...

Страница 386: ... TPD32 EV 386 ...

Страница 387: ... Instruction manual 387 ...

Страница 388: ... TPD32 EV 388 ...

Страница 389: ... Instruction manual 389 ...

Страница 390: ... TPD32 EV 390 ...

Страница 391: ... Instruction manual 391 ...

Страница 392: ... TPD32 EV 392 ...

Страница 393: ... Instruction manual 393 ...

Страница 394: ... TPD32 EV 394 ...

Страница 395: ... Instruction manual 395 ...

Страница 396: ... TPD32 EV 396 ...

Страница 397: ... Instruction manual 397 ...

Страница 398: ... TPD32 EV 398 ...

Страница 399: ... Instruction manual 399 ...

Страница 400: ... TPD32 EV 400 ...

Страница 401: ... Instruction manual 401 ...

Страница 402: ... TPD32 EV 402 ...

Страница 501: ... Instruction manual 501 APPENDIX 3 ACCESSORIES A3 1 EAM Adapter Kit EAM1579 EAM1580 ...

Страница 503: ......