Page 8

mounted in the lower half of the storage tank. Boiler temperature controls are typically mounted in the primary

loop. If the temperature control sensor is mounted directly on the heater/boiler water piping, the sensor must be

installed on the inlet water piping to prevent short cycling of the appliance.

A water flow switch must be installed by the installer and wired to prevent the unit from firing if for any reason

there is an inadequate flow of water through the boiler/heater (see wiring diagrams for suggested location in the

electrical circuit).

NOTE: CSD-1 model boilers only, are equipped with a factory installed operating

aquastat.

Optional, circulation pumps can be supplied for single or three phase and 115 to 460 volts as required. The

pump power must be wired independently and should be adequate for the amp rating of the pump motor. Refer

to the Operating Instructions and Wiring Diagrams sections of this manual for more information regarding

pumps.

GAS REQUIREMENTS

Ensure the fuel the appliance will burn is the same as that specified on the boiler

rating plate. Conversions must be completed by a Qualified Service Agency or Gas

Provider. Call your Green Boiler Technologies Representative or Customer Service

for instructions and the proper conversion kit.

The gas supply meter, regulator, and piping must have sufficient capacity to supply all gas fired appliances they

feed without undue pressure loss. If the gas meter, regulator or piping is too small, request the gas company

install equipment with adequate capacity.

The allowable pressure loss in gas piping between the gas meter or service regulator and each appliance is

generally between 0.3 to 0.5 inches of water column. Refer to the National Fuel Gas Code, ANSI Z223.1, Latest

Edition, for sizing guidelines.

Example:

For 20 equivalent feet of 1-1/2 inch piping, the maximum cuft/hr gas flow with a 0.3 inch w.c.

pressure loss is 726. For natural gas at 1025 Btu/cuft, the maximum firing rate is 744,000 Btu/hr

[726 x1025]. For propane at 2500 Btu/cuft, the maximum firing rate is 1,815,000 Btu/hr [726 x

2500].

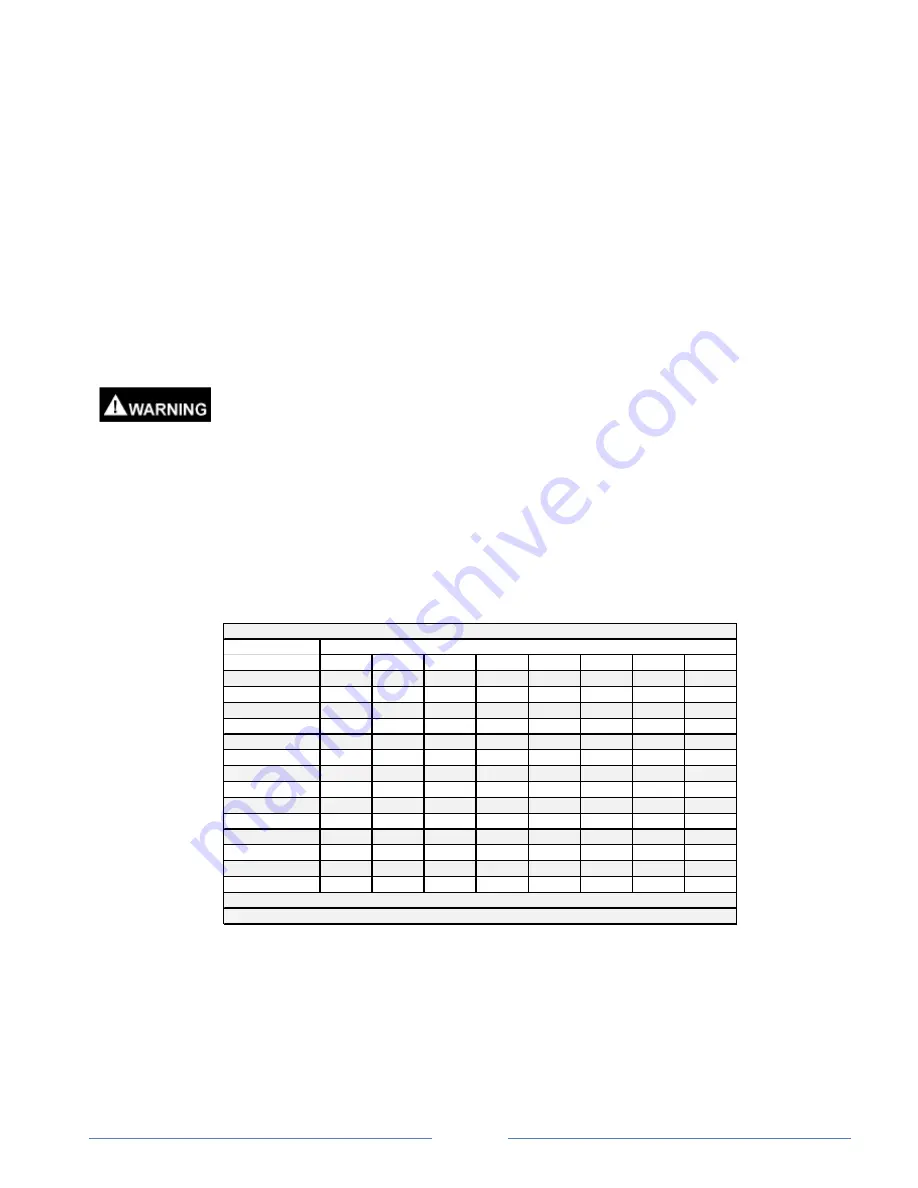

Maximum and minimum gas pressure delivered to the boiler/heater is shown below. If the gas supply line

pressure is greater than the maximum listed, a pressure regulator must be installed at least 10 pipe diameters

upstream of the boiler/heater.

Max Length

(Equivalent feet)

3/4

1

1-1/4

1-1/2

2

2-1/2

3

4

10

273

514

1060

1580

3050

4860

8580

17500

20

188

353

726

1090

2090

3340

5900

12000

30

151

284

583

873

1680

2680

4740

9660

40

129

243

499

747

1440

2290

4050

8270

50

114

215

442

662

1280

2030

3590

7330

60

104

195

400

600

1160

1840

3260

6640

70

95

179

368

552

1060

1690

3000

6110

80

89

167

343

514

989

1580

2790

5680

90

83

157

322

482

928

1480

2610

5330

100

79

148

304

455

877

1400

2470

5040

125

70

131

269

403

777

1240

2190

4460

150

63

119

244

366

704

1120

1980

4050

175

58

109

224

336

648

1030

1820

3720

200

54

102

209

313

602

960

1700

3460

Gas Pipe Sizing Chart: Cubic Feet of Gas Per Hour

Size Schedule 40 Metal l ic Pipe (i nches)

Ta bl e Va l ue s For Na tura l Ga s , Spe ci fi c Gra vi ty 0.60

Typical Natural Gas = 1025 Btu per cuft ; Typi cal Propane = 2,500 btu/cuft

Содержание A2-035

Страница 30: ...Page 29 DIAGRAMS...

Страница 31: ...Page 30...

Страница 33: ...Page 32 WIRING DIAGRAM A2000 Water Heater Models...

Страница 34: ...Page 33 WIRING DIAGRAM A2000 Boiler Models...

Страница 35: ...Page 34 WIRING DIAGRAM A2000 CSD 1 Boiler Models...

Страница 36: ...Page 35 A2000 WITH CONSTANT PUMP OPERATION A2000 WITH ON OFF PUMP OPERATION...

Страница 37: ...Page 36 A2000 WITH INFITEC PUMP DELAY...

Страница 38: ...Page 37 A2000 PARTS LIST 1 17 19 15 23 22 21 20 18 16 4 2 Gas Train Components Differ By Model 7 14 5...

Страница 44: ......