12

PA2

(2nd stage - 2nd pause) then appears on the display for 3 seconds, follo-

wed by the time set previously or nothing, meaning you need to set the time.

Use the + / - keys on the keyboard to set or change the time (accepted range:

00.5 - 50.0 minutes, with steps of 00.5 = 30 seconds). Press

key P

to confirm.

After confirming the time

SP3

(3rd stage - 3rd temperature level) appears for

3 seconds, followed by the temperature set previously or nothing, meaning you

need to set the temperature. Use the + / - keys on the keyboard to set or change

the temperature (accepted range: 20 °C - 60 °C, with steps of 0.5°C). Press

key P

to confirm.

PA3

(3rd stage - 3rd pause) then appears on the display for 3 seconds, followed

by the time set previously or nothing, meaning you need to set the time.

Use the + / - keys on the keyboard to set or change the time (accepted range:

00.5 - 50.0 minutes, with steps of 00.5 = 30 seconds).

Press

key P

to confirm.

QUITTING THE PROGRAM

After confirming the third stage with

key P

, you quit programming mode and the

led

stops flashing.

CAUTION:

The temperature values

SP1

and

SP3

must be higher than that for

SP2

(as SP2 is a work cycle that requires a

lower temperature). If this is not the case, the machine buzzer will sound and the set values will not be accepted.

You should then set the temperature levels again.

NEW MACHINE

The new machine is supplied with three programs already set for three types of chocolate; these

programs can, however, be modified.

The data for these three programs are provided on a sheet enclosed with the machine (page 30).

PREPARING THE MACHINE

ADDING THE PRODUCT

- remove the cover (05);

- add the product. NB: max capacity: 3.50 kg (nominal tub capacity: 5 l);

It's important that the products (chips or flakes) is evenly distributed in the basin on either side of the dividing wall;

- replace the cover.

To speed up the work cycle, you can pour the preheated product into the basin (max 35 °C).

CAUTION:

Never add any chocolate until the machine has finished its previous work cycle.

STARTING THE WORK CYCLE (Start)

Having chosen the program and adding the product to the basin, simply press

Start

(see keyboard). The heating

lamps inside the machine now start to heat up. The temperature is shown on the display; this rises gradually until

the set

SP1

(1st level) value is reached.

The display constantly shows the temperature of the chocolate throughout the work cycle.

Start work cycle

(basin rotation)

1st stage (heating)

The basin starts rotating once the 1st level temperature

SP1

has been reached.

The temperature remains constant in the basin for pause

PA1

.

2nd stage (cooling)

The cooling fan now starts to cool the chocolate to the

SP2

temperature.

The temperature is then kept constant thanks to the lamps during pause

PA2

.

3rd stage (final heating)

The temperature starts rising again (thanks to the heating lamps) until it reaches the set

SP3

value.

The temperature is then kept constant during pause

PA3

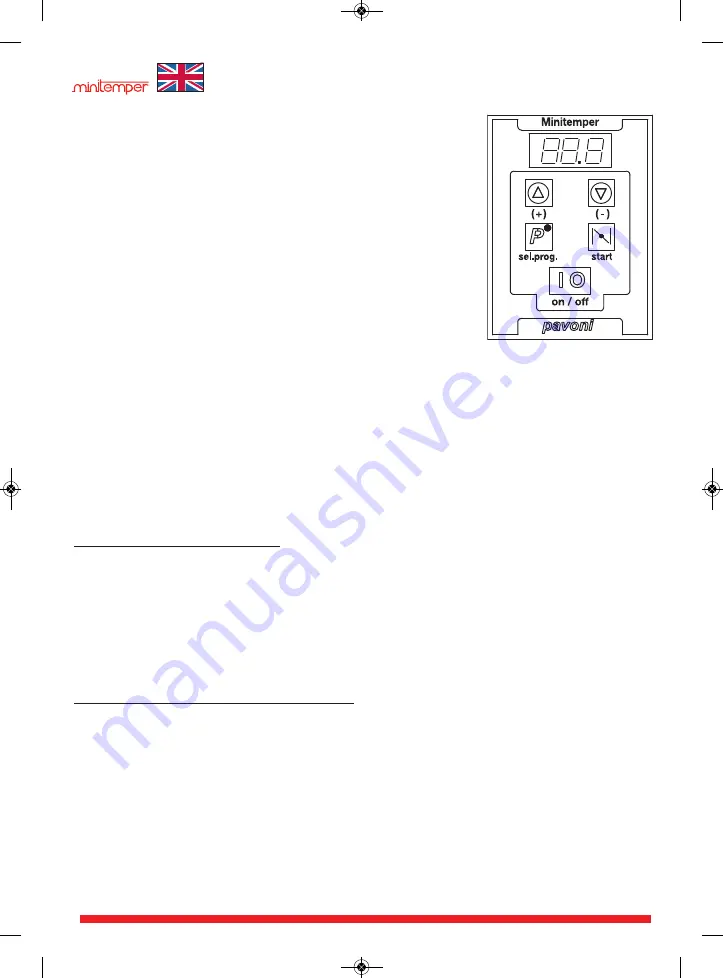

MACHINE KEYBOARD

piegh minitemper 12_2016.qxp_piegh minitemper 15/12/16 08:19 Pagina 12

Содержание Minitemper

Страница 1: ......

Страница 2: ...ITALIANO 5 ENGLISH 10 FRAN AIS 15 DEUTSCH 20 ESPA OL 25...

Страница 29: ......