HIWARM

A

B

F

E

C

D

30

All copying, even partial, of this manual is strictly forbidden

RG66007967 - Rev 02

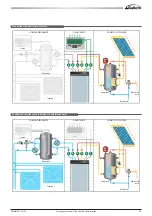

Domestic hot

water

Water mains

Storage tank

Storage tank

Fan coil

Flooring

REMOTE UNIT

DOMESTIC HOT WATER

HOME ENVIRONMENT

Cooling, dehumidification and simultaneous production of domestic hot water,

alternated with excess heat dissipation to the coil.

3.6

PIPING AND LOAD DESIGN CRITERIA

All the copper pipes are made according to our specifications for the construction process to be fully controlled and implicitly

improve the quality of our products. Each pipeline complies with the requirements of Directive 97/23PED and is verified by

FEM code at the most stressed 180° bending point and at the maximum pressure allowed by the safety components while

also considering adequate safety coefficients.

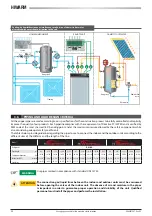

The tables below provide guidelines regarding the pipes to use to connect the indoor and the outdoor units according to the

different sizes of the HiWarm and the length of the line:

Model

012

022

033

Refrigerant

R410A

Pipe length

m

0-5

6-10

11-15

16-20

21-25

0-5

6-10

11-15

16-20

21-25

0-5

6-10

11-15

16-20

21-25

Compressor frequency

Hz

30-120

30-120

30-120

30-120

30-120

20-120

20-120

20-120

20-120

20-120

20-120

20-120

20-120

20-120

20-120

Intake line (GAS)

mm-in

16-5/8"

16-5/8"

16-5/8"

18-3/4"

18-3/4"

18-3/4"

18-3/4"

18-3/4"

22-7/8"

22-7/8"

22-7/8"

22-7/8"

22-7/8"

28-1 1/8"

28-1 1/8"

Liquid line

mm-in

10-3/8"

10-3/8"

10-3/8"

10-3/8"

10-3/8"

12-1/2"

12-1/2"

12-1/2"

12-1/2"

12-1/2"

16-5/8"

16-5/8"

16-5/8"

16-5/8"

16-5/8"

WARNING

Use pipes marked in compliance with standard UNI 12735.

ATTENTION

The connection gas/liquid lines between the indoor and outdoor units must be vacuumed

before opening the valves of the indoor unit. The absence of air and moisture in the pipes

is important in order to guarantee proper operation and durability of the unit. Qualified

personnel must install the pipes and perform the installation.