Page

28

of

42

Fuji Electric Europe GmbH

11. Settings

11.4 Specific settings for induction motors in open loop (geared motors without encoder)

For induction motors auto tuning has to be performed before the first travel. The brake stays applied. To do so, the

parameters described in the table below must be set.

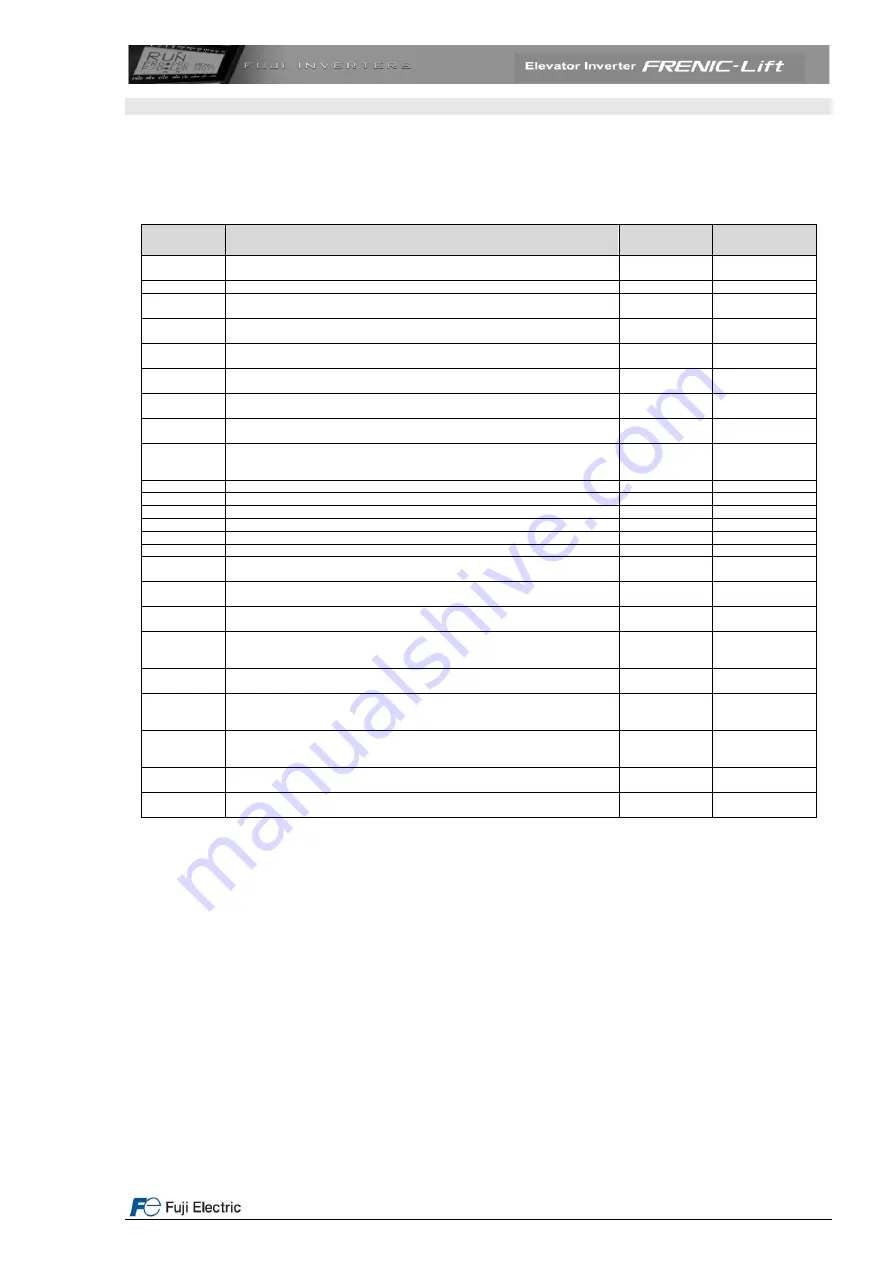

Table 21. Basic setting for induction motor in open loop

Function

Meaning

Factory

setting

Setting

E46

Language setting (clear text function description)

1

Depends on the

country

C21

Speed selection units (C21=0: rpm, C21=1: m/min or C21=2: Hz)

0

2

P01

Motor number of poles from manufacturer data sheet or motor name plate

Must be set before setting F03 value!

4

Depends on the

motor

F03

Motor’s rated speed (from motor’s name plate). The units are always rpm (not

dependant on C21 setting). Normally F03 is motor speed at nominal lift speed

1500 rpm

Depends on the

motor

L31

Maximum linear (in m/min) speed corresponding to F03 value. Used as

linearization factor for speed settings

60.0

Depends on the

installation

F04

Motor’s synchronous speed. The units depend on the setting of function C21.

For 4-pole motors (50Hz) is 1500 r/min, for 6-poles motors (50Hz) is 1000 r/min

1500 rpm

Depends on the

motor

F05

Motor rated voltage from name plate (V)

380 V

Depends on the

motor

F09

Torque boost

0.0%

Depends on the

application

F11

Overload detection level

Depends on the

inverters

capacity

Same as P03

F20

DC

– Braking (Start speed)

0.00 rpm

0.20 Hz

F21

DC

– Braking (Level)

0%

50%

F22

DC

– Braking (Time)

0.00 s

1.00 s

F23

Start speed

0.00 Hz

0.50 Hz

F24

Start speed (Hold time)

0.00 s

1.00 s

F25

Stop speed

3.00 rpm

0.20 Hz

F42

Control type selection (for 37 and 45kW Dynamic torque vector control is not

available)

0

2

P02

Motor rated capacity (power) from name plate in kW

Depends on the

inverter capacity

Depends on the

motor

P03

Motor rated current from name plate in A

Depends on the

inverter capacity

Depends on the

motor

P04

Auto tuning mode.

P04=1: measures P06 and P07 values

P04=3: measures P07, P08 and P12 values and calculates P06 value

0

3

P06

Motor no-load current in A. The Auto tuning procedure calculates, the value of

this function (when P04=3). The calculation overwrites the factory setting

Depends on the

inverter capacity

Automatic

P07

Motor stator resistance (R1) in %. The Auto tuning procedure measures the

value of this function (when P04=1 or 3). The measurement overwrites the

factory setting

Depends on the

inverter capacity

Automatic

P08

Motor stator reactance (X1) in %. The Auto tuning procedure measures the value

of this function (when P04=1 or 3). The measurement overwrites the factory

setting

Depends on the

inverter capacity

Automatic

P12

Slip frequency in Hz. The Auto tuning procedure measures the value of this

function (when P04=3). The measurement overwrites the factory setting

0.00 Hz

Automatic

L83

Delay time for closing (applying) the brake after the speed is under stop speed

(F25)

0.10 s

0.00 s

Auto tuning procedure (executed from input terminals) in 5 steps

To perform the described procedure the enable (EN1&EN2) inputs must be active.

1. Is the motor correctly connected?

2. Turn on inverter mains supply

3.

Please set the functions described in the above table

4. Set function P04 to 3 and press FUNC/DATA

5. Give RUN command to the inverter from the lift controller (normally in INSPECTION mode). The main

contactors will be closed and current will flow through the motor producing some acoustic noise. This

procedure will take some seconds. After this auto tuning procedure is finished.