Page

27

of

42

Fuji Electric Europe GmbH

n

n

V

L

I

L

33

,

4

05

11. Settings

11.3 Specific settings for permanent magnet synchronous motors

For permanent magnet synchronous motors pole tuning has to be performed before the first travel. The brake stays

applied. To do so, the parameters described in the table below must be set.

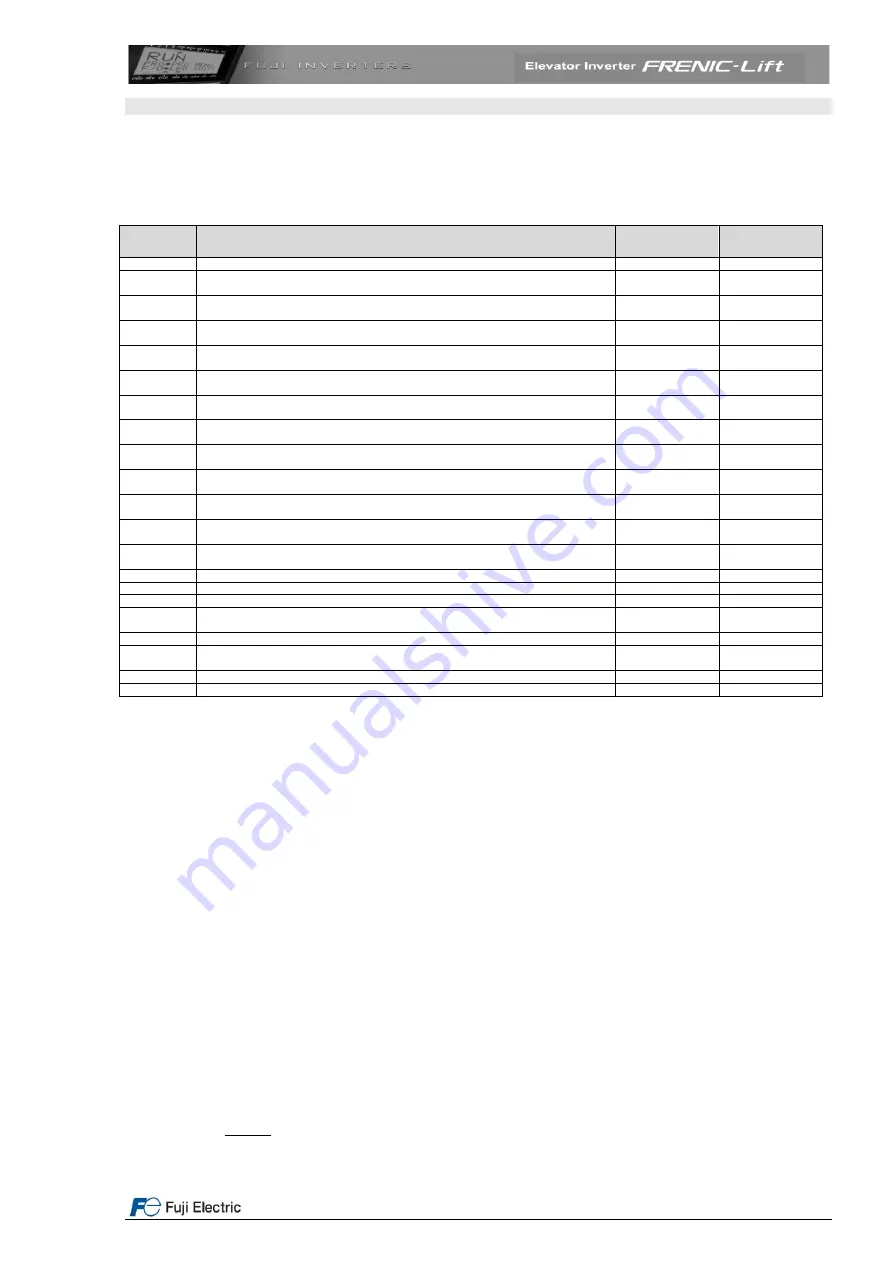

Table 20. Basic setting for synchronous motor

Function

Meaning

Factory

setting

Setting

H03

Initialization of factory settings for synchronous motors

0

2

L01

Encoder type: ECN 1313 EnDat 2.1 or ERN 1387 (or compatible) is possible. See

information from manufacturer data sheet or encoder name plate

0

4 for Endat 2.1

5 for ERN1387

Remove power supply from the inverter for a short time (ensure that Keypad is

completely off)

E46

Language setting (clear text function description)

1

Depends on the

country

C21

Speed selection units (C21=0: rpm, C21=1: m/min or C21=2: Hz)

0

Depends on the

installation

P01

Motor number of poles from manufacturer data sheet or motor name plate

Must be set before setting F03 value!

20

Depends on the

motor

F03

Motor’s maximum speed. The units are always rpm (not dependant on C21 setting).

Normally F03 is motor speed at nominal lift speed

60 rpm

Depends on the

motor

L31

Maximum linear (in m/min) speed corresponding to F03 value. Used as linearization

factor for speed settings

60.00

Depends on the

installation

F04

Motor’s rated speed (from motor’s name plate). The units depend on the setting of

function C21

60 rpm

Depends on the

motor

F05

Motor rated voltage from name plate (V)

380 V

Depends on the

motor

F11

Overload detection level

Depends on the

inverters capacity

Same as P03

P02

Motor rated capacity (power) from name plate in kW

Depends on the

inverters capacity

Depends on the

motor

P03

Motor rated current from name plate in A

Depends on the

inverter capacity

Depends on the

motor

P06

Motor no-load current in A (for synchronous motor set this function to 0)

0 A

0 A

P07

Motor stator resistance R1 in %

5%

5%

P08

Motor stator reactance X1 in %

10%

10%

L02

Encoder resolution (pulses per revolution) from manufacturer data sheet or name plate

2048 p/rev

Depends on the

encoder

L04

Offset angle obtained from pole tuning

0.00

Automatic

L05

Current loop controller (ACR) P gain

1.5

Depends on the

motor

L36

Speed loop controller (ASR) P gain at high speeds

2.50

2.00

L38

Speed loop controller (ASR) P gain at low speeds

2.50

2.00

Pole tuning procedure in 7 steps:

To perform the described procedure the enable (EN1&EN2) inputs must be active.

1. Are motor and encoder connected properly?

2. Apply power to the inverter

3. The functions mentioned in the table above must be set.

Check that the inverter receives the encoder pulses as following: in the keypad go to Menu

4. I/O Check

and

press the down arrow key until you reach the page that shows P1, Z1, P2 and Z2 (8/8). If the motor is not moving,

the display should show

+0 p/s

after P2. Open (release) the brake and turn a little bit the motor. In this moment

the display should show a number different than 0 (positive or negative depending on the rotation direction). If the

display shows

----p/s

(or

+0 p/s

meanwhile the motor is turning) means that no signal is coming from the encoder.

In this case please check the encoder cable and the connection of the signals.

4. Set function

L03 to 1

and press FUNC/DATA key.

5. Give RUN command to the inverter from the lift controller (normally in RESCUE or INSPECTION mode). The

main contactors will be closed and current will flow through the motor producing some acoustic noise. This

procedure will take some seconds. After the procedure was finished correctly the offset value is saved and

shown in function

L04

. Write down the displayed value. If Er7 is displayed check the motor and encoder cabling

and repeat steps 5 and 6.

6. If possible, open the brake and let the cabin move some centimetres.

7. Perform steps 5 and 6 again. The result in function L04 between different measurements must not differ more

than ± 15°.

L05: Current loop regulator (ACR) P gain calculation

L=Motor inductance (minimum value between Ld and Lq) [mH]

V

n

=Motor rated voltage [V] (F05)

I

n

=Motor rated current [A] (P03)