5.4 List of Periodic Replacement Parts

Each part of the dynamic breaking unit has its own service life that will vary according to the environmental and operating

conditions. It is recommended that the following parts be replaced at the specified intervals.

When the replacement is necessary, consult your Fuji Electric representative.

Table 5.4-1 Replacement Parts

Part name

Standard replacement intervals (See

Note

below.)

DC link bus capacitor

10 years

Electrolytic capacitors on printed circuit boards

10 years

Cooling fans

10 years

Fuses 10

years

Note

These replacement intervals are based on the dynamic breaking unit’s service life estimated at an ambient

temperature of 30

°

C. In environments with an ambient temperature above 40

°

C or a large amount of dust or dirt, the

replacement intervals may be shorter.

Notes for periodic replacement of parts

(1) The replacement intervals listed above are a guide for almost preventing parts from failure if those parts are replaced

with new ones at the intervals. They do not guarantee the completely fault-free operation.

(2) The table above does not apply to unused spare parts being kept in storage. It applies only when they are stored in a

well-ventilated, cool and dark place and energized approximately once a year.

(3) Cooling fans can be replaced by users. As for other parts, only the persons who have finished the Fuji Electric training

course can replace them. For the purchase of spare cooling fans and the request for replacement of other parts, contact

the sales agent where you purchased the product or your nearest Fuji Electric representative.

5.5 Insulation Test

Since the dynamic breaking unit has undergone an insulation test before shipment, avoid making a Megger test at the

customer's site.

If a Megger test is unavoidable for the main circuit, observe the following instructions; otherwise, the dynamic breaking unit

may be damaged.

A withstand voltage test may also damage the dynamic breaking unit if the test procedure is wrong. When the withstand

voltage test is necessary, consult your Fuji Electric representative.

(1)

Megger test of main circuit

1) Use a 1000 VDC Megger and shut off the main power supply without fail before measurement.

2) If the test voltage leaks to the control circuit due to the wiring, disconnect all the wiring from the control circuit.

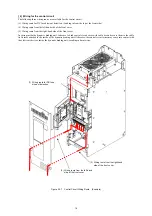

3) Connect the main circuit terminals with a common line as shown in Figure 5.5-1.

4) The Megger test must be limited to across the common line of the main circuit and the ground ( ).

5) Value of 5 M

or more displayed on the Megger indicates a correct state. (The value is measured on an dynamic breaking

unit alone.)

Figure 5.5-1 Main Circuit Terminal Connection for Megger Test

(2) Insulation test of control circuit

Do not make a Megger test or withstand voltage test for the control circuit. Use a high resistance range tester for the control

circuit.

1) Disconnect all the external wiring from the control circuit terminals.

2) Perform a continuity test to the ground. One M

or a larger measurement indicates a correct state.

(3) Insulation test of external main circuit and sequence control circuit

Disconnect all the wiring connected to the dynamic breaking unit so that the test voltage is not applied to the dynamic

breaking unit.

27

Содержание BUC S-69D

Страница 8: ......