74

Corrections dur-

ing welding

To obtain the best possible welding results, the arc-force dynamic parameter will some-

times need to be adjusted.

Press the "Parameter selection" button to select the arc-force dynamic parameter

Use the adjusting dial to set the desired arc-force dynamic value

The welding parameter value is shown in the digital display located above it.

HotStart function

To obtain optimum welding results, it will sometimes be necessary to adjust the HotStart

function.

Advantages

-

Improved ignition, even when using electrodes with poor ignition properties

-

Better fusion of the base material during the start-up phase, meaning fewer cold-shut

defects

-

Largely prevents slag inclusions

For details on setting the available welding parameters, please refer to "Setup parame-

ters", "Setup menu - level 2".

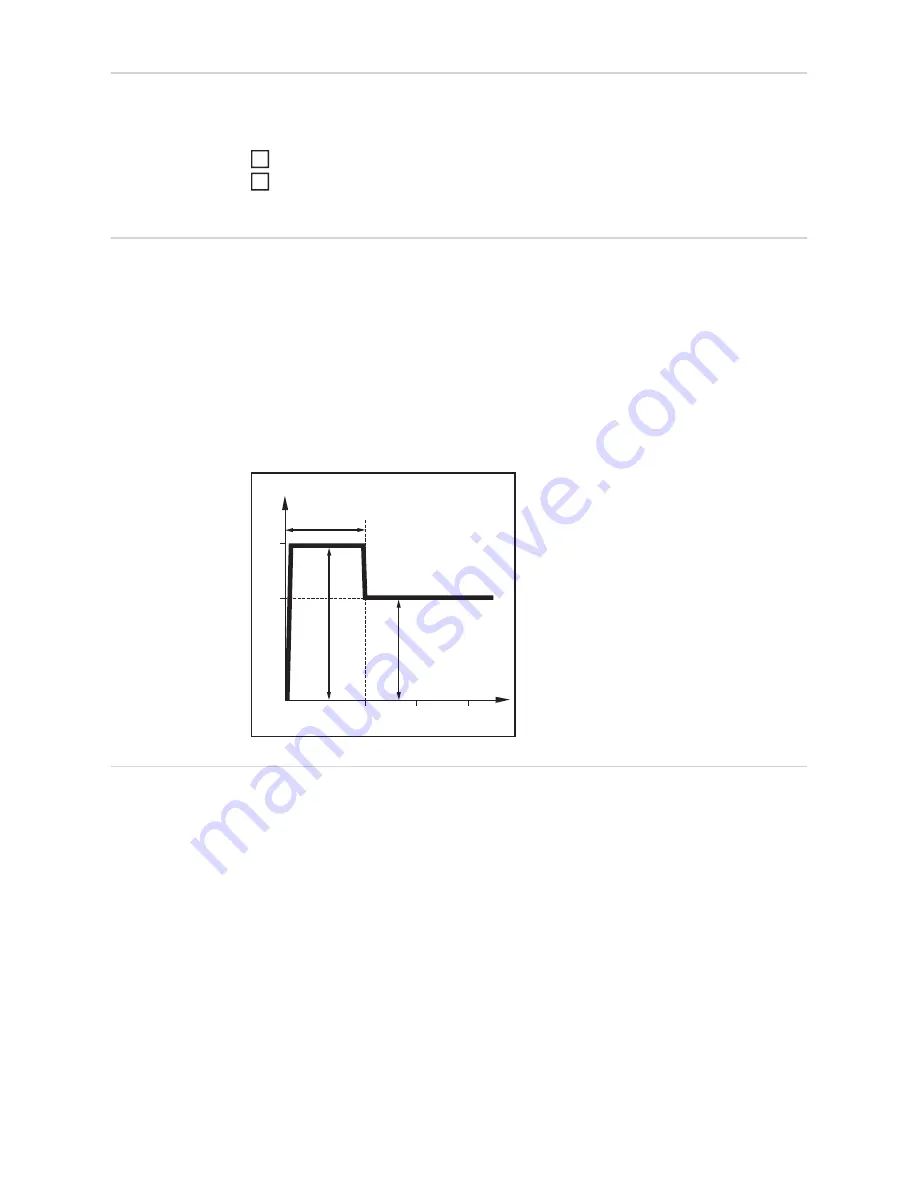

Legend

Hti: Hot-current time,

0 - 2 s, factory setting: 0.5 s

HCU: HotStart-current,

100 - 200 %, factory setting 150 %

I

H

: Main current = set welding current

Function

During the specified hot-current time (Hti),

the welding current is increased to a certain

value. This value (HCU) is higher than the

selected welding current (I

H

).

Anti-stick func-

tion

As the arc becomes shorter, the welding voltage may drop so far that the rod electrode will

tend to "stick". This may also cause "burn-out" of the rod electrode.

Electrode burn-out is prevented by activating the anti-stick function. If the rod electrode be-

gins to stick, the power source immediately switches the welding current off. After the rod

electrode has been detached from the workpiece, the welding operation can be continued

without difficulty.

The anti-stick (Ast) function can be activated and deactivated in the Setup parameters in

"Setup menu: level 2".

1

2

200

300

I (A)

Hti

HCU > I

H

t (s)

I

H

HCU

0,5

1

1,5

Содержание VR 5000 noSpool

Страница 2: ...2...

Страница 4: ...4...

Страница 19: ...General information...

Страница 20: ......

Страница 25: ...Control elements and connections...

Страница 26: ......

Страница 41: ...Installation and commissioning...

Страница 42: ......

Страница 44: ...44 The VR 5000 noSpool without an integrated wirespool holder may only be set up and op erated in closed areas...

Страница 51: ...51 EN 1 2 1 2...

Страница 54: ...54 1 Contact pressure standard values U groove roll ers Steel 4 5 CrNi 4 5 Tubular cored electrodes 2 3 1 1...

Страница 58: ...58...

Страница 59: ...Welding...

Страница 60: ......

Страница 76: ...76 Number 3 Number 4 Number 5...

Страница 77: ...Setup settings...

Страница 78: ......

Страница 92: ...92...

Страница 93: ...Troubleshooting and maintenance...

Страница 94: ......

Страница 105: ...Technical data and settings tables...

Страница 106: ......

Страница 123: ...Appendix...

Страница 125: ...125...

Страница 126: ...126 E Euro connection Connectors F Fronius connection FSC Fronius system connection TW Tweco connection...

Страница 127: ...127 8 8 8 8 5 5 5 Motor Plate Alu 4R s Connector Motor...

Страница 128: ...128...

Страница 129: ...129...

Страница 130: ...130...

Страница 131: ...131...