________________________________________________________________________________

31

AST 14 C 255/00

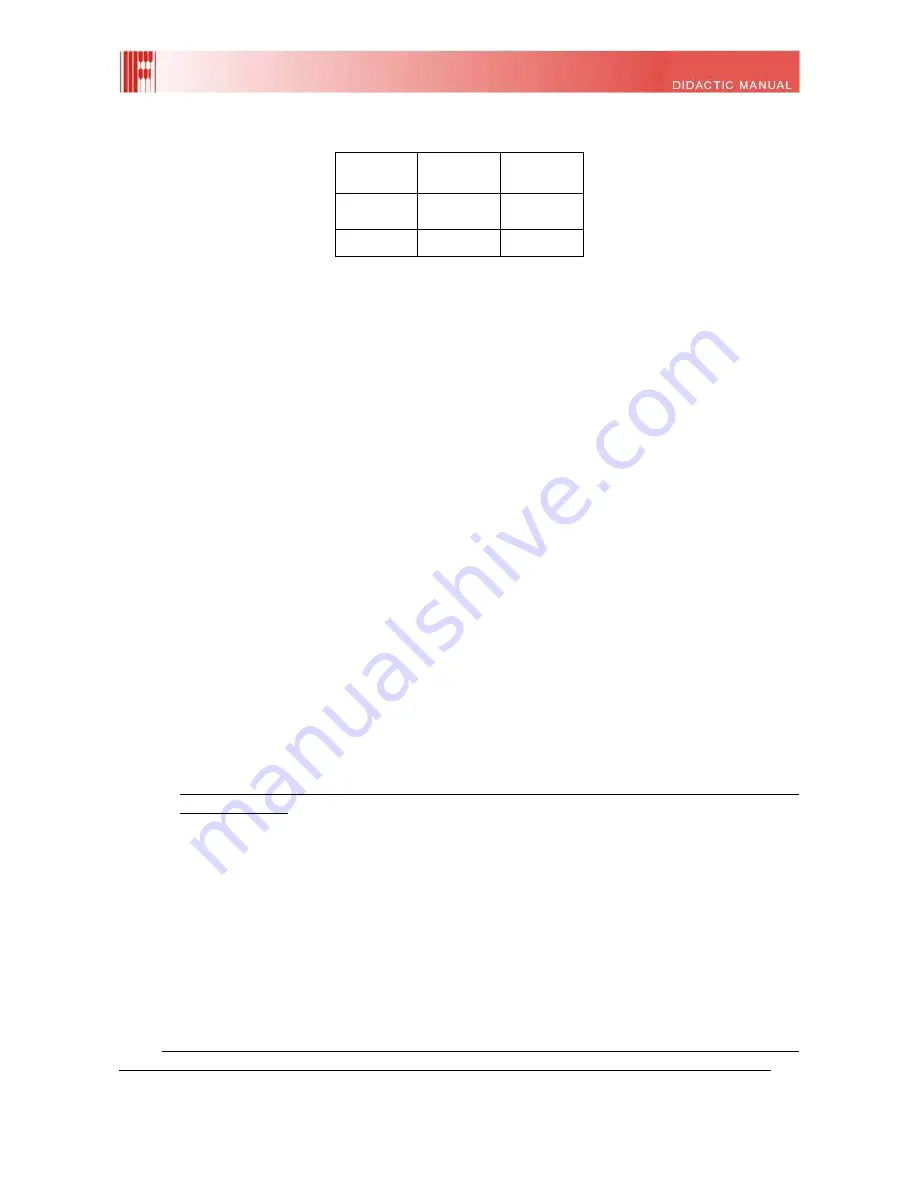

The current supplied to the modulation coil at the minimum and at the maximum output

values according to the gas used are given below:

max

[mA]

min

[mA]

Natural

gas

120 20

LPG

170 30

Release the “+” or “- DHW” keys to return to the previous page showing the current at the

modulation coil and the flow temperature.

The burner is switched off when the temperature detected by the flow probe exceeds 90°C

and switched on again when reaching 70°C.

During such function the pump is supplied with power, the three-way valve switches to the

heating position, and the multifunction relay is energised with parameter P17=1 (remote

relay) or P17=3 (heating relay).

The function automatically stops after 15 minutes, or by pressing the "reset" key, or setting

a mode different from the “CH+DHW” one.

WARNING: the connected zone boards, if any, will also transfer the heat as a result of

mixing valve setting, thus enabling the zone pump to maintain the flow set-point.

4.3 GAS CONVERSION

Boilers are manufactured to run on the type of gas (natural gas or LPG) specifically

required upon purchase order placing, and any conversion shall be made by qualified

personnel.

During gas conversion, proceed as follows:

make sure to work with the boiler disconnected from the electric power supply;

remove combustion chamber front panel;

remove burner upper part concerning gas ramps;

remove burner nozzles and replace them with new ones having a diameter

suitable for the new gas type (see "setting" paragraph on page 9).

WARNING: it is mandatory to fit the copper gaskets supplied along with the

conversion kit;

refit burner and combustion chamber;

supply the boiler with power;

access parameter setting page, and set parameter P0 to the value suitable for the

type of gas used (refer to the sequence described in the "parameter editing" on

page 33):

P0

1 = 24 kW natural gas

P0

0 = 24 kW LPG

P0

3 = 28 kW natural gas

P0

2 = 28 kW LPG

P0

5 = 32 kW natural gas

P0

4 = 32 kW LPG

gas valve can now be set (paragraph 4.1).

N.B. “Polidoro” burners feature as a standard nozzles without copper washers. It is

mandatory to fit them during conversion. Failure to do so may affect the proper sealing.