2. Measure the resistance to check the status of the sensor and wiring according to the values in

(page 27).

3. Measure between each sensor lead to earth (ground) to establish that the resistance is infinite (or at

least several Megaohm).

Check the leakage sensors

If the pump is connected to the MAS monitoring system, then it is recommended that the sensors be

checked in the MAS unit. Otherwise, use a multimeter.

1. Check the float switch (FLS) in the stator housing, according to the values in

(page 27).

Measure ohms by using a multimeter to establish either of the conditions below (or both if the sensor

is accessible).

2. Check the float switch (FLS) in the junction box (connection housing).

3. Check the water-in-oil sensor (CLS) in the oil housing:

a) Connect the CLS to a 12 V DC supply.

The sensor must have the correct polarity in order to be checked. However, it will not be damaged

if plus and minus are switched.

b) Use a multimeter as an ammeter, and connect it in series with the sensor.

c) If the sensor is accessible, check: the alarm function by gripping the sensor in your hand.

Skin and blood tissue contain a high content of water.

For interpretation of the CLS measurement results, see

(page 27).

Empty the coolant (integrated cooling)

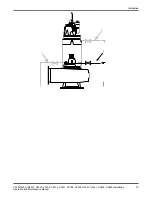

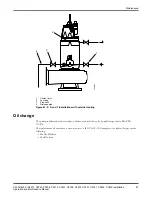

WARNING:

The cooling jacket must be drained before service.

1. Remove the vent plug marked “1” in the figure below.

2. Depressurize the cooling system by opening the stop-cock marked “2” in the figure below (if

applicable).

3. Remove the coolant filling plug and empty the coolant through the drainage pipe, marked “3” in the

figure below.

4. After you empty the cooling jacket on P and S installations, run the pump run dry for no more than

30 seconds to expel all water from the impeller area.

Maintenance

C3300/6x5, C/R3231, C3240, C3306, C3312, C3351, C3356, C3400, C3501, C3531, C3602, C3800 Installation,

Operation and Maintenance Manual

85

Содержание C/R3231

Страница 2: ...End of Disclaimer text ...

Страница 4: ......

Страница 170: ......

Страница 171: ......